This shipping Bracket parts are for chairs, which are fixed on & support the chair back, and connect with the chair legs.

This shipping Bracket parts are for chairs, which are fixed on & support the chair back, and connect with the chair legs.

The chair back aluminum brackets mould be desinged with right and left brackets in one mould.

The die casting brackets were be drilled and screwed, surface be polished and applied by shot blasting.

In the furniculture production processes, Aluminum and Zinc alloy injection parts are widely be used.

Such as Chair arms, foot / legs, connect-joint parts, desk support parts etc.

For all chairs or desks die casting parts, KYLT can provide shot blasting, normal / bright polish, color painting, color powder coating, plating etc surface treatments.

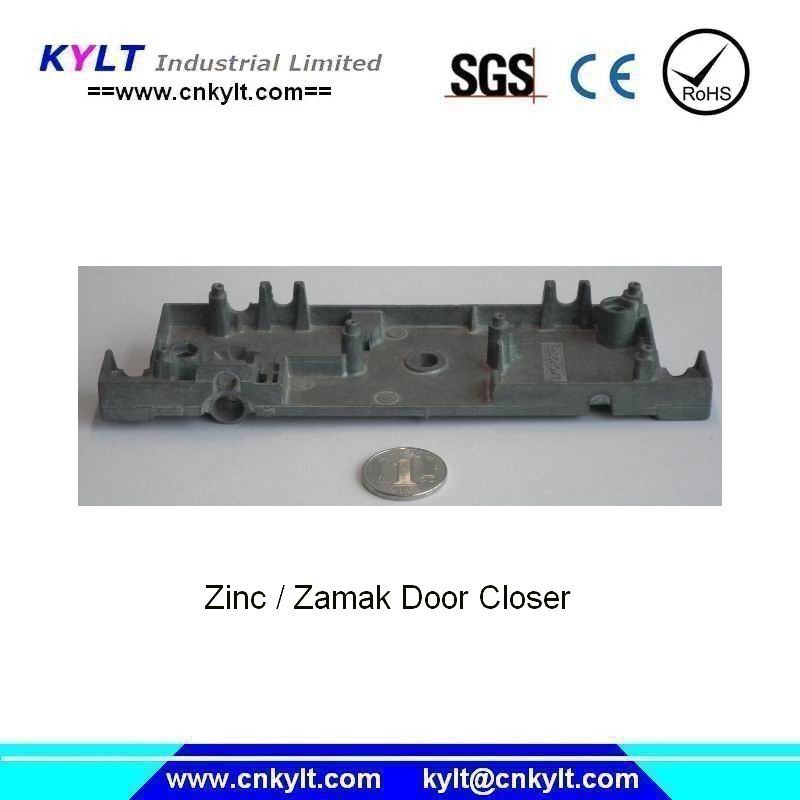

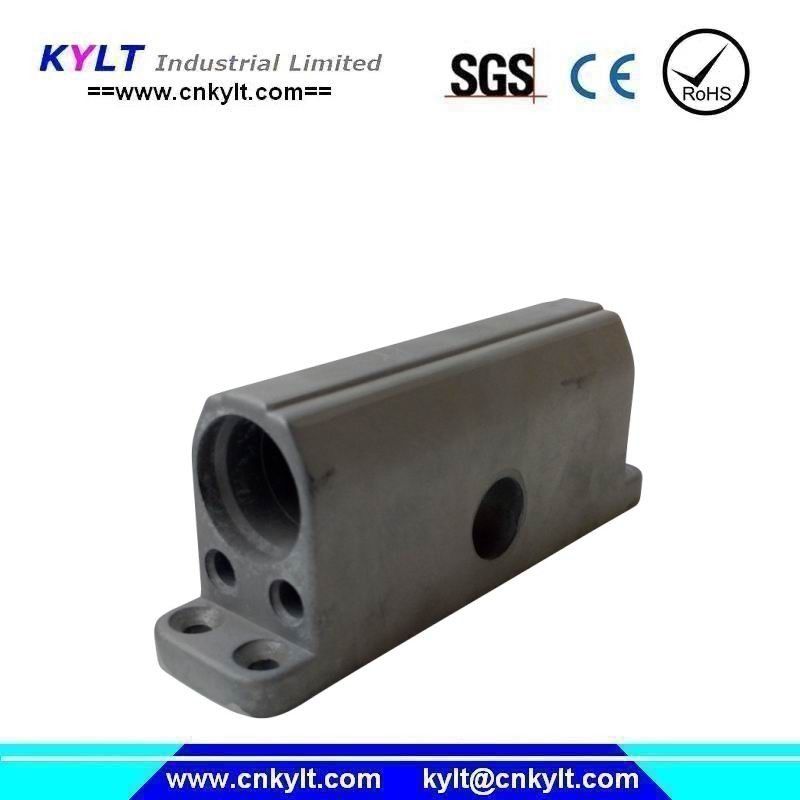

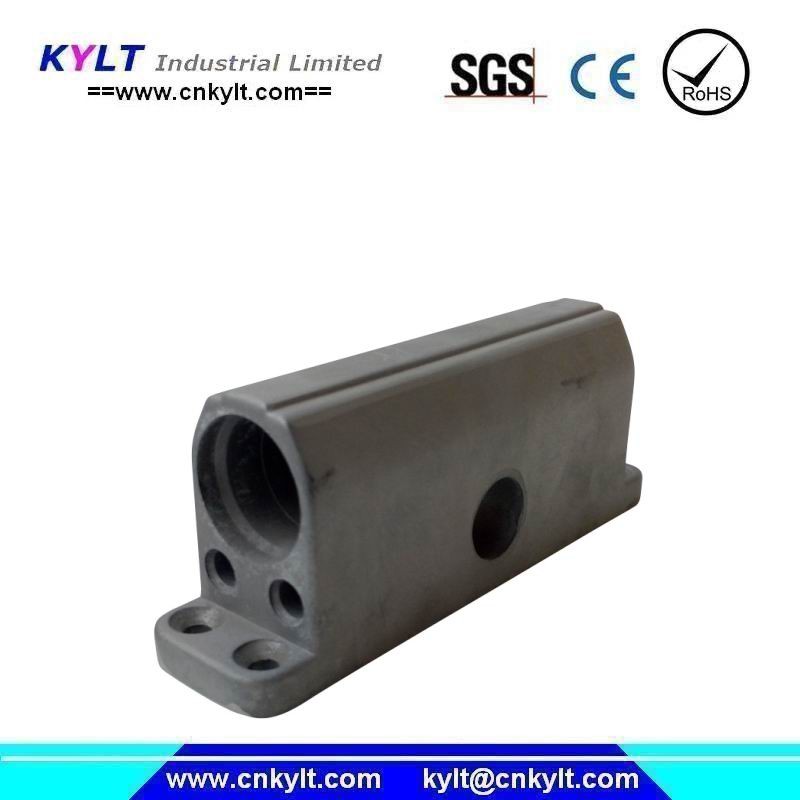

As Aluminum Zamak alloy die casting manufacturer, KYLT casting parts also involves all industrial lines which need Aluminum and Zinc Components.

And KYLT provide "one-stop" service from production to shipment.

For more informations, please feel free to contact with us:

Stone

www.cnkylt.com

Email: stonechenpeng@aliyun.com ; kylt@cnkylt.com

Skype: stone.chenpeng

Mob: 0086-15195010186

Msn: stonechenpeng@hotmail.com

KYLT Customerized Aluminum/Zinc/Zamak alloy metal die casting parts

Products Of Aluminum Zinc Alloy Description:

KYLT Industry Co., Ltd. is a professional die casting manufacturer in China.

KYLT focus on samll-middle enterprises, provide die casting solutions as per clients demands from Moulds making, Aluminum / Zinc (Zamak) / Lead (PB) Metal Alloy Die Casting to Machining, Surface treatment, Assembly and Shipment etc.

Our Aluminum Zinc Die Casting Parts are vary from home appliances, office appliances, precise automotive industries to spare parts of industry hardware and etc

With good quality, KYLT die casting parts are export to Japan, Spain, English, Germany, USA etc.

Equipments List:

|

MACHINES NAME |

QTY |

TYPE |

CAPACITY |

REMARK |

|

Hot chamber die casting machines |

3sets |

Horizontal |

30T-88T |

Full-auto |

|

Cold chamber die casting machines |

4sets |

Horizontal |

180T-500T |

Manual, Full-auto |

|

CNC |

4sets |

|

|

|

|

Other machines |

Drilling machines, Polishing machines, Milling machines etc |

Aluminum Die Casting Materials:

-ADC12, A380 etc

Zinc (Zamak) Die Casting Materials:

-Zamak2, Zamak3, Zamak5, Zamak7, ZA8, ZA27 etc.

Moulds Making:

-Moulds design, making, maintain in house

-(OEM) Customer provides UG, Solidworks, CAD drawings etc

-(ODM) Customer show us detail ideas and requirements, our engineers will to design.

-Molds productions period is about 3 to 4 weeks.

-Provide die casting samples for customer to check.

Die Casting:

--7sets die casting machines, 2 or 3 shifts to guarantee production in time.

--Experienced die casting and mould makers, 7*24 await orders to guarantee moulds and machines running good.

--Only use standard enviroment friendly Aluminum, Zamak alloy materials. Provide MATERIAL CERTIFICATE from original material factory.

--Provide CE, ROHS, SGS certificate as per customer requirements.

Machining:

--Finish lathing, drilling, tapping, milling, CNC machining works in house

Surface Treatment:

--As per customer requirements, KYLT provide die casting parts surface treatments methods: deburring, shot blasting, shacking polishing by machine (smooth polish or light polish), manual normal polishing, manual bright polishing, painting, powder coasting, galvanization,chrome plating etc.

Packing and shipment:

--FOB, CFR, CIF, EXWORKS trade term available.

--Packing by cartons and in pallets.

--Die casting samples can be send by DHL, FEDEX, UPS, TNT, EMS etc

For more informations about aluminum zinc alloy Aluminum Alloy Pressure Molding Chair Arms Parts, please feel free to contact with us:

Stone

www.cnkylt.com www.zamakcast.com

Email: stonechenpeng@aliyun.com ; kylt@cnkylt.com

Skype: stone.chenpeng

Mob(whatsapp): 0086-15195010186

Msn: stonechenpeng@hotmail.com