20T High Pressure Hot Chamber Die Casting Machine has improved on the basis of other similar type machines. We adopts worldwide famous brands of electrical appliance and hydraulic component, high reliability, high efficiency of production, high automation. The zinc alloy, lead alloy and tin alloy which is manufactured by the machine has the good surface quality, and can be polishing, electrofacing, and spray lacquer. And it is widely used in manufacturing toy, lockset, fishing gear, hardware decorating parts, electrical and electronic casting, automobile part, watchcase, clothing metal accessory and so on.

20T Hot Chamber Die Casting Machine Specification and Parameters:

| NAME |

PARAMETERS |

NAME |

PARAMETERS |

|

Locking Force

|

200KN |

Motor Power |

5.5KW |

| Tie Bars Inner Space |

235×245mm |

Bladder accumulator Capacity |

16L |

| Moving Clamping Plate |

125mm |

Vane Pump Working Pressure |

7.0Mpa |

| Profiling Thickness |

110 – 190mm |

Electric Heating Tube Power |

6.9KW |

| Clamping Pressure |

20KN |

Heater Hand Power |

1KW |

| Clamping Stroke |

72mm |

Oil Tank Capacity |

170L |

| Dosage of Fluid Metal Per shot(Zn) |

220g |

Machine Weight |

约1450Kg |

| Crucible Effective Capacity(Zn) |

110Kg |

Machine Dimensions |

250×90×180cm |

| Vane Pump |

28L/min |

|

|

Important matters in hot chamber die casting machine operation:

1. Anti-wear hydraulic oil of hydraulic system should be one of below, and should be kept clean.

--N46﹟or N68# Anti-wear hydraulic oil

2. Check and adjust bracket guideway regularly (6 months), and keep its horizontality (vertical, horizontal) in 0.2mm/m.

3. Lubricant of centralization lubrication should be one of below, and should be kept clean.

--20# or 30# lubricant (machine oil)

4. Grease fitting on manual lubrication part should be lubricated by 20# or 30# lubricant everyday.

5. Accumulator should be filled with nitrogen.

6. Prohibit demolish safety door and safety device.

7. Prohibit demolish or change oilway, electric system parts and structure privately.

8. When new machine is used in the first three months. If the injection system stops more than 3min, the injection plunger should be taken out.

9. Melting furance should be started at 350℃, when temperature reach 350℃, keep the temperature for 10min, and then adjust to working temperature.

Safety attentions of hot chamber die casting machine operation:

1. Prevent electric shock

--Machine should connect ground well.

--Prohibit to simplify safety protection device.

--Select suitable power wire sectional area.

--Check the cover of electric wire usually, if it is broken, it should be changed.

--Before switch on, all electrical box and terminal box should be closed.

--Prohibit to touch parts of electrical appliance after the machine starts.

2. Prevent burning

--Wear protective clothes to protect body, and to protect spark and iron filings entering human body.

--Avoid putting alloy with oil, water or other things into smelter.

Installation of die casting machine and its preparation before starting:

A. High pressure die casting machine transportation

1. Machine transportation:

Check equipment and its hoisting position before lifting, and confirm its weight according to technology parameter sheet in order to use suitable lifting equipment.

2. Attentions:

(1)When lifting, lock mode should be at right position.

(2)Equipment should be fixed during transportation.

(3)Prevent terminal box and operation panel, nitrogen cylinder and smelter, safety door and other protection device from being damaged.

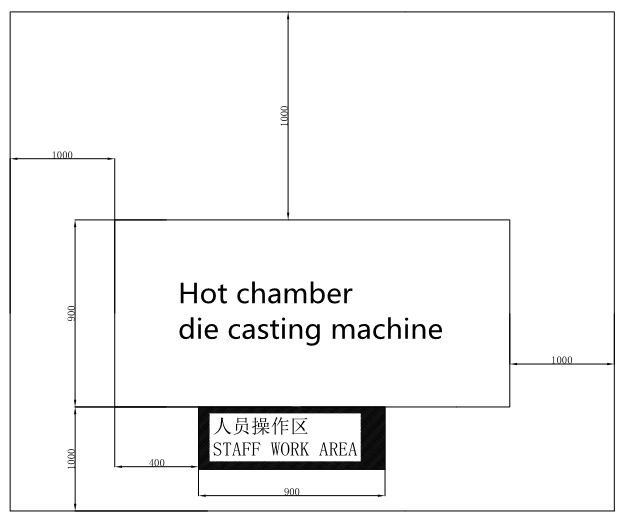

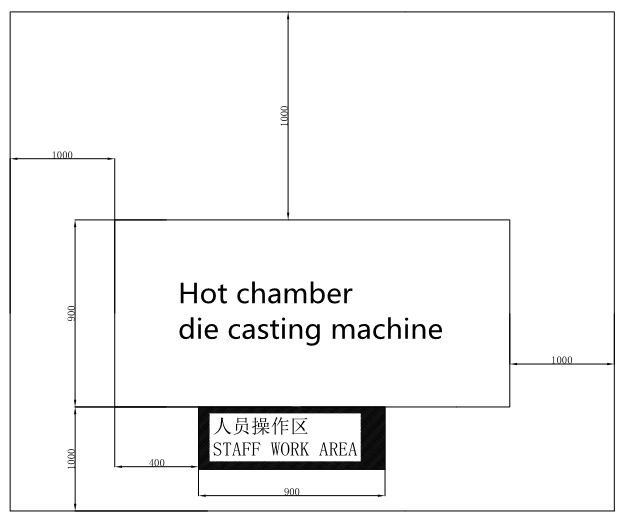

B. Hot chamber die casting machine operation environment

(1)Equipment should work at normal temperature.

(2)Ensure adequate lighting.

(3)Leave 1-2 meters of empty space around equipment.

C. Preparation before die casting machine installation

Before installation, there should be some preparations.

1. Connect with cooling water

Attentions of using cooler: use clean soft water; pressure of cooling water can’t over 5Bar; pour off water from cooler when stop machine under freezing temperature for a long time, in case freezing; check cooler every six-month for if it is unobstructed.

2. Melting furance

Adjust temperature to 60℃ before using it, and check the heat tube if it works normal.

3. Releasing agent (prepared by customer):

Its function is to make products separate from die easily. According to ratio requirement of releasing agent products, add water into water-based die release agent until it becomes release agent aqueous solution.

4. Connecting method of power wire

External wire R,S,T and N enters electric box through incoming hole at the bottom of main electric box, and connects to relevant terminal.

Notes:

(1)voltage AC380V, 50Hz, three phase four wire

(2)Current 50A, power 13KW

(3)diameter of phase wire: 4mm, diameter of wire N: 2.5mm

(4)equipment should be connected with ground before it starts (connecting with cooling water)

The above information is only for reference, all operations should be monitored by relevant operator.

5. Hydraulic oil and lubrication oil

(1) Choose suitable anti-wear hydraulic oil and lubrication oil

(2) Tank should be filled with hydraulic oil, and the oil temperature feet should be submerged by oil.

(3) Centralized lubricating system should be lubricated once or twice before normal use, and during its using period, it should be lubricated automatically and regularly.

(4) Grease fitting of centralized lubricating system should be lubricated once before use, and during normal using period, it should be lubricated once a day.

(5) Work temperature should be 15℃-55℃.

6. Cement platform

(1) Put die casting machine at a smooth cement platform.

(2) The size of cement platform is according to the size of equipment, and there should be space around the machine for installation hole. The space should be 1-1.5 meters. Shock absorbers can be used for keeping balance.

(3) There should be tunnel around the platform in order to avoid machine oil and water spilling out.

D. Turn on melting furance

1. Start cooling water circulation system before turning on melter, in case that clamping oil cylinder and silicon seal will be damaged by high temperature.

2. Don't turn on heating pipe until alloy liquid be filled into melter and submerge the heating pipe. If there is no alloy liquid, melt metal alloy by using liquefied gas spray gun. And before the heating pipe being submerged by alloy liquid, it can’t be turned on to avoid being damaged.

3. Turn on melter, and adjust temperature to 320℃-350℃, after 10 minutes adjust it to work temperature. During this period, put solid alloy material into melter when there is no solid alloy in melter. Turn on heating ring, after temperature reaches 400℃.

4. Alloy liquid should be beyond the melter cup clamping plate when start machine. The distance of alloy liquid and crucible can’t be more than 1cm.

Attentions:

(1) During the early three months of using this machine, clamping rod should be taken out, if the machine stops or the clamping system stops for more than 3 minutes.

(2) Melter can't be turned on, if cooling water circulation system doesn't work, and it can't be stopped more than half an hour during working period.

(3) Solid alloy should be put into melter slowly, otherwise people may be hurt by spurting melting liquid.

E. Install and demolish nozzle body

1. Check the conformance of nozzle body and crucible, and ensure that there is no zinc alloy residue at the neck of crucible, then put nozzle body into crucible by hand and revolve around to check whether the taper of nozzle body is contacted closed.

2. Hit nozzle body once to twice by copper rod (or zinc pig but not use iron).

3. Check the conformity of nozzle body and die centre (their distance to the centre can’t be more than 0.3mm)

4. Preheating heating ring to 400℃ before demolish nozzle body, then take down heating ring, and revolve nozzle body clockwise by pipe wrench and take it down. If can’t revolve the nozzle body, rap the up and down or so the four directions by copper rod (or zinc pig).

F. Install injection plunger

1. Put clamping stem into smelter and preheat it with alloy, and take out it when the temperature reaches 400℃;

2. Put injection plunger into melt cup, and put on connect cover.

3. close insurance of connect cover

Attentions:

(1) Ensure the clamping stem can turn flexible after being put into melt cup.

(2) Ensure that there is no alloy residue on clamping stem when it is put into melt cup lest it wouldn't stuck in melt cup.

G. Heating ring

1.Normal work temperature is 400-450℃.

2.When use heating cover, the temperature should be controlled above a certain temperature, otherwise the alloy liquid may be condensed in nozzle body.

WARNING: the maximum work temperature is 480℃, higher temperature will lead to shorten heating ring's lifetime, and may cause the heating ring to be burnt up.

H. Install melt cup

Melt cup can be installed after releasing pressure of equipment's oil pressure system and demolish clamping system. If the equipment is being used, take out alloy liquid until its surface is below melt cup and then take out heating tube. After take out melt cup, remove alloy residue at the combine place of melt cup and crucible.

1.Put melt cup at the crucible's substrate, and make them be combined closely without shaking gap.

2.Install melt cup clamp on melt cup, and install clamping system, then install holder screws (daub high temperature grease on thread of every screws before they are being installed) and tighten them.

Attentions:

Advising to use old abrasive clamping stem with new melt cup in order to avoid being stuck.

I. Install nozzle head

According the feeding mouth's size of die to choose suitable nozzle head and install it.

1.Ensure that there is no alloy residue at the combine place of nozzle head and nozzle body.

2.Put nozzle head into nozzle body's cone hold, and ensure that there is no gap between them and the concentricity is good.

3.Rap the top of nozzle head by copper rod (or zinc pig), start the equipment which has been installed die, operate compound die and keep taut action, and make nozzle head pressure in nozzle body for 1 minute.

4.Tighten taut institution, and adjust position of support screws.

Hot chamber die casting machine operation instruction

Revolve all of knobs at the middle position when the equipment doesn't work and is checked.

1. Manual operation

Revolve automatic-manual selection knob to manual position and then revolve Semiauto-Auto knob to the middle position, press start button.

2. Semiauto operation

Revolve automatic-manual selection knob to automatic position and then revolve "Semiauto-Auto" knob to "Semauto" position, press start button.

3. Fullauto operation

Revolve automatic-manual selection knob to automatic position and then revolve "Semiauto-Auto" knob to "Auto" position, press start button.

Attentions:

if the signal warning light of feeding door doesn't turn on, automatic cycle will stop until the light turn on.

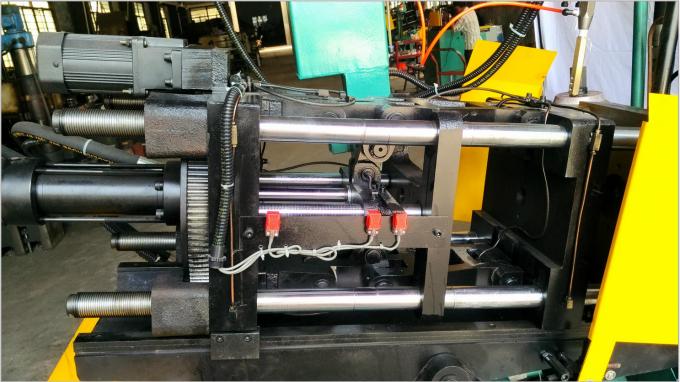

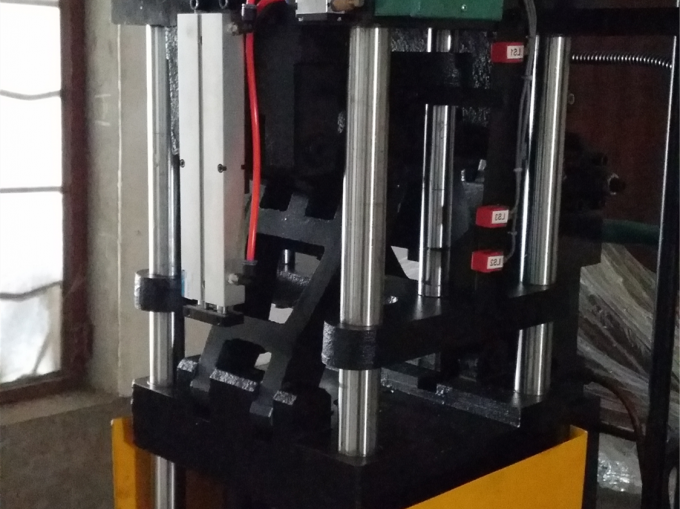

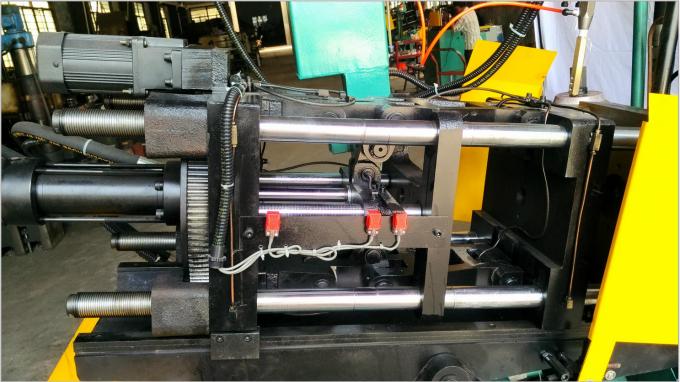

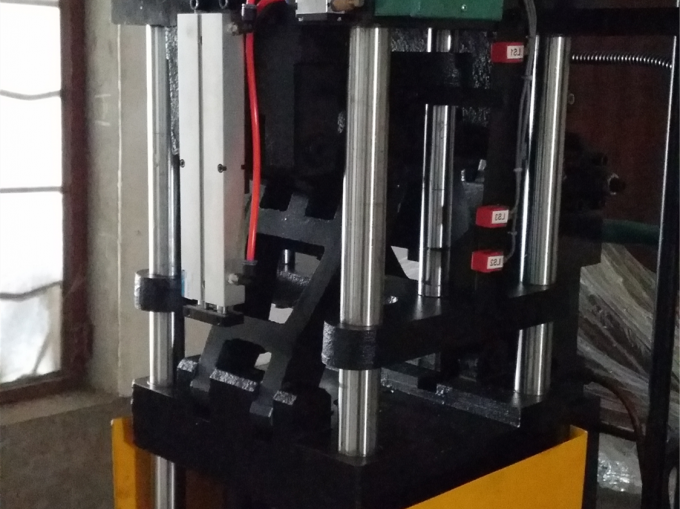

20T Hot Chamber Die Casting Machine Features:

-

Auto-mould height adjustment: ensure fast adjusting, stable clamping and high durability.

2. Adopt integrated injection cylinder, which has high efficiency, stability and safety.

3. Mold closing protective system can protect operator's security, and reduce mold damage probability.

4. The central automatic lubrication system has the function of regular and quantitative safety detection at the same time to ensure the normal lubrication of the mechanical system.

5. Control panel with easy operation and safe locking protection design.

6. Reliable and durable automatic sprayer assures fast and stable production.

7. The improved melting furnace adopts advanced design and material, more energy saving and durable.

8. Mold closing/opening adopts electronic fix detecting system, and its precision is higher.

9. The alarm information can be found conveniently and timely.

10. Injection operation, opening and locking mould design etc. can be set on the screen rapidly and accurately.

11. High-strength steel alloy tie bar with chromium plated for high wear resistance and long service life.

12. Thickened platen was made of excellent ductile cast iron with high rigidity, even stress and little distortion, which ensures the stability of die casting machine.

13. Diagonal five point toggle was made of ductile cast iron with high rigidity, high durability, and more stable mold opening and closing.

14. The heat treated parts of the injection system are made of high-quality hot processed steel.

About small 20T horizontal die casting machine price, or die casting mould, please feel free to email us: cnkylt@aliyun.com We will choose suitable machine types, suggestions of mould design, provide free die casting samples.

Related Casting Machinery:

Die Casting Machine

· Battery Spine Die Casting Machine

· Cold Chamber Die Casting Machine

· Hot Chamber Die Casting Machine

· Vertical Die Casting Machine

· PDC casting machine

Material

· Aluminum Die Casting Machine

· Magnesium Die Casting Machine

· Copper Die Casting Machine

· Zinc Die Casting Machine

· Lead Die Casting Machine

Application

· Auto Parts Die Casting Machines

· Kitchen &Household Parts Die Casting Machines

· Lamps Light Parts Die Casting Machines

· Electric Vehicle Spare Parts Die Casting Machines

· Hardware, Jewelry, Clothing Accessories Die Casting Machines

· Tel-Communication Equipment Parts Die Casting Machines

· Garden Machinery & Electric Tools Parts Die Casting Machines

· Lead Acid Battery Terminal Bushing, Battery Positive Spine Grid Die Casting Machines

· Fishing Sinker Die Casting Machines

· Others