LZ300T Pressure Die Casting Machine has high productivity, adjustable injection positions suitable for more molds; Die casting mold life long, aluminum alloy dies life about 30,000 to 50,000 injection times; Easy to achieve mechanization and automation. Over 35 years experience of the die casting machine design and manufacturing. Email: cnkylt@aliyun.com

DC300T Pressure Die Casting Machine Specification (LZ300T)

| No. |

ITEM |

UNIT |

LZ300 |

| 1 |

Clamping Force |

KN |

3000 |

| 2 |

Inner space between tie bars(H*V) |

mm |

580×580 |

| 3 |

Die Stroke |

mm |

450 |

| 4 |

Die Thickness |

mm |

250~650 |

| 5 |

Ejection Stroke |

mm |

110 |

| 6 |

Ejection Force |

KN |

150 |

| 7 |

Injeciton Force |

KN |

133~300 |

| 8 |

Injection position(center is "0",down is "-") |

mm |

0,-160 |

| 9 |

Dia. of shot sleeve |

mm |

50,60,70 |

| 10 |

Dia.of Injection chamber flange |

mm |

110f7 |

| 11 |

Over height of flange |

mm |

12-0.05 |

| 12 |

Dosage of fluid metal pershot |

kg |

3.2(Al.) 2.3(Mg.) |

| 13 |

Projected area |

cm |

196~800 |

| 14 |

Injection pressure |

Mpa |

35~143 |

| 15 |

Dry cycle |

s |

10 |

| 16 |

Oil tank capacity |

L |

750 |

| 17 |

Motor power |

KW |

18.5 |

| 18 |

Machine sizes(L*W*H) |

M |

6.4×1.6×2.8 |

(Remark: 1.The die casting machine supplier keeps the right to revise above parameters, If there is any alterations, advance notice won't be given then. 2. Servo die casting machine can be choosed to save energy and cost. )

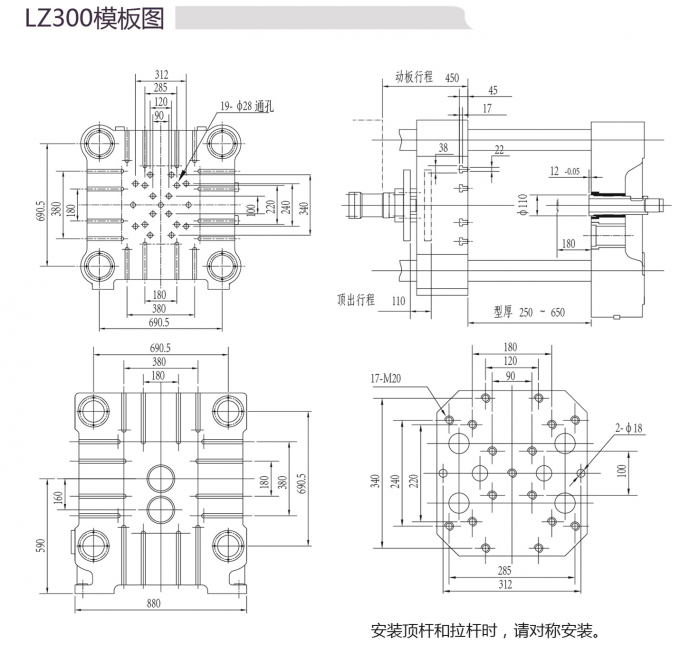

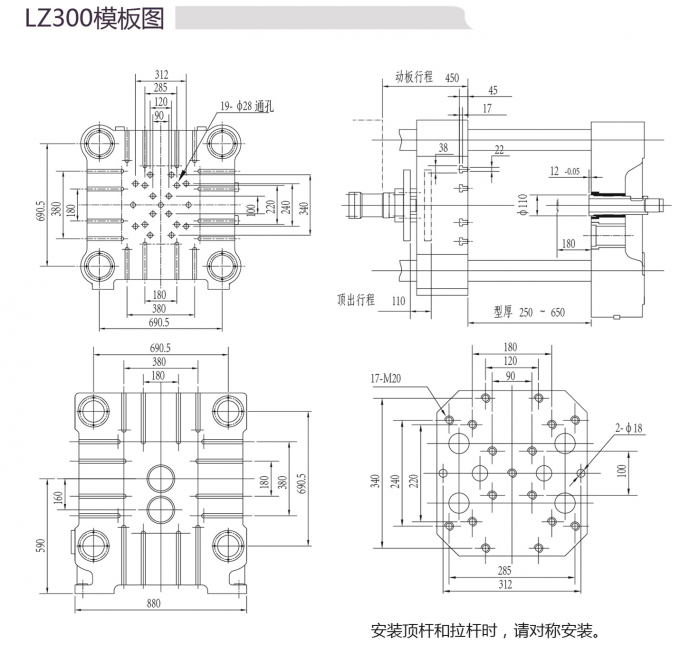

LZ 300T Pressure Die Casting Machine Molding Plate Specification:

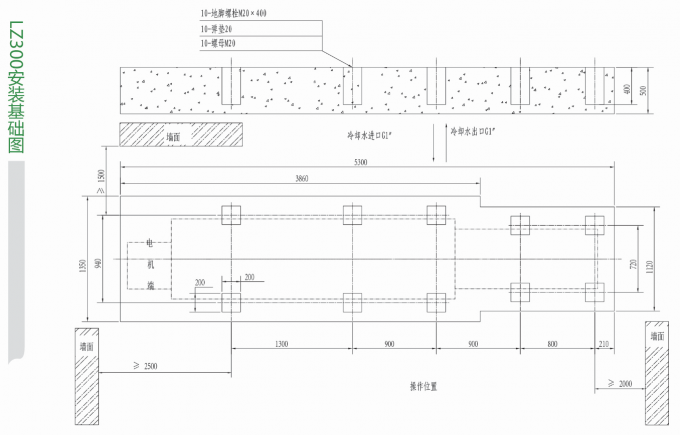

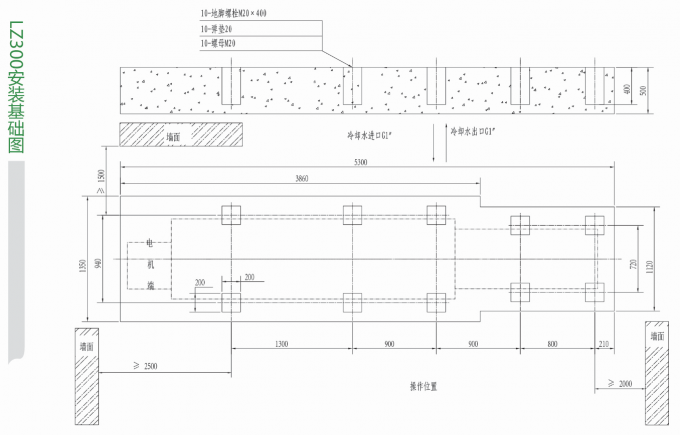

LZ 300T Pressure Die Casting Machine Cement Ground Specification:

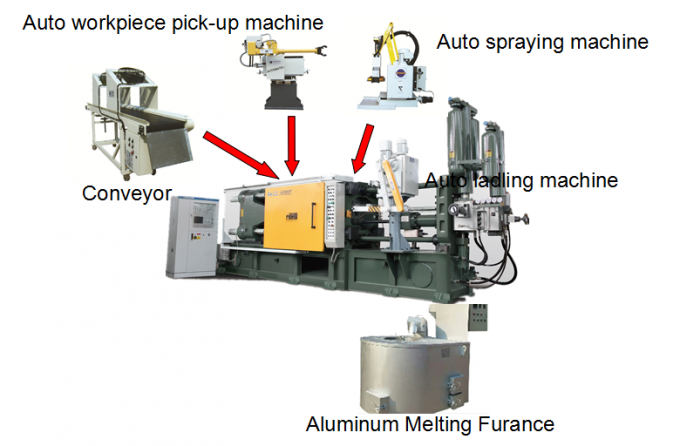

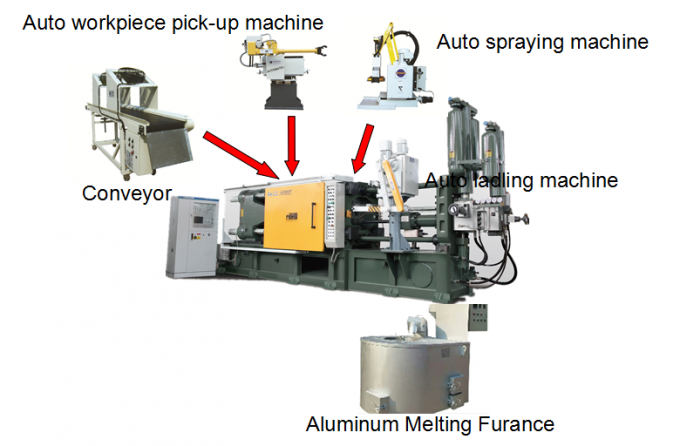

Cold chamber die casting machine working process?

-

In manual working process: die casting opeartor pour molten aluminum alloy from furance to cold chamber, then casting machine inject metal to die tool to get the die casting parts.

-

In full automatic working process: Die casting machine PLC control the whole process. Automatic ladler pour molten aluminum metal alloy from melting pot to die casting machine cold chamber. Then, be inject to mold cavities to got die-cast parts. Auto extractor pick-up casting part from die tool, put them on conveyor. The auto sprayer cooling and lubricating the mold cavity. And, to start then next die casting process.

High Pressure Die-Cast Machine Structure

-

Machine body with hydraulic oil tank

Green structure is die casting machine body, also is hydraulic oil tank.

-

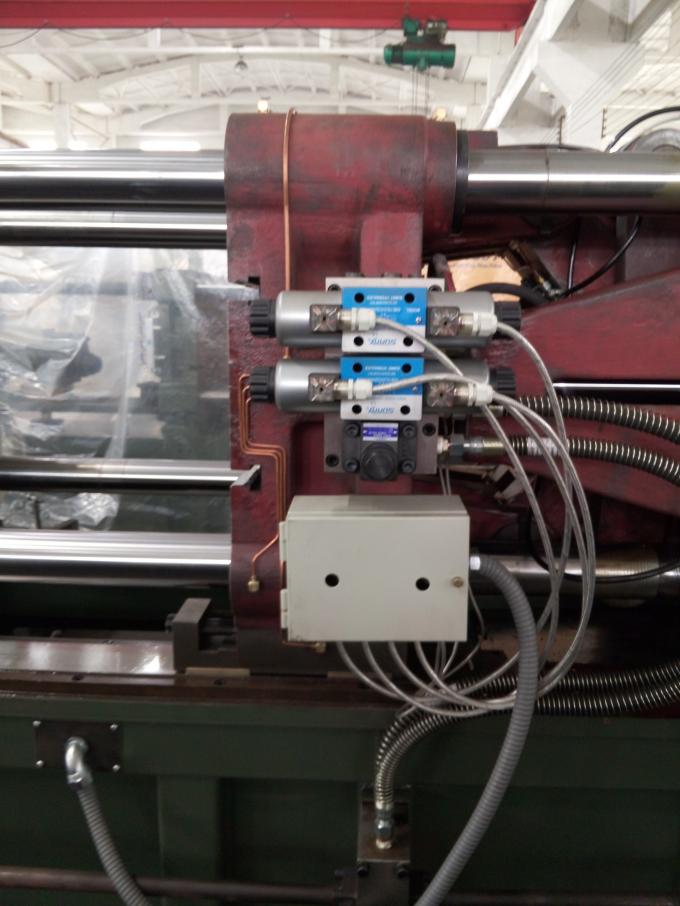

Accumulation system

-

Lubrication system

-

Mould height adjusting mechanism

Hydraulic driven gear-type used to adjust die casting die.

-

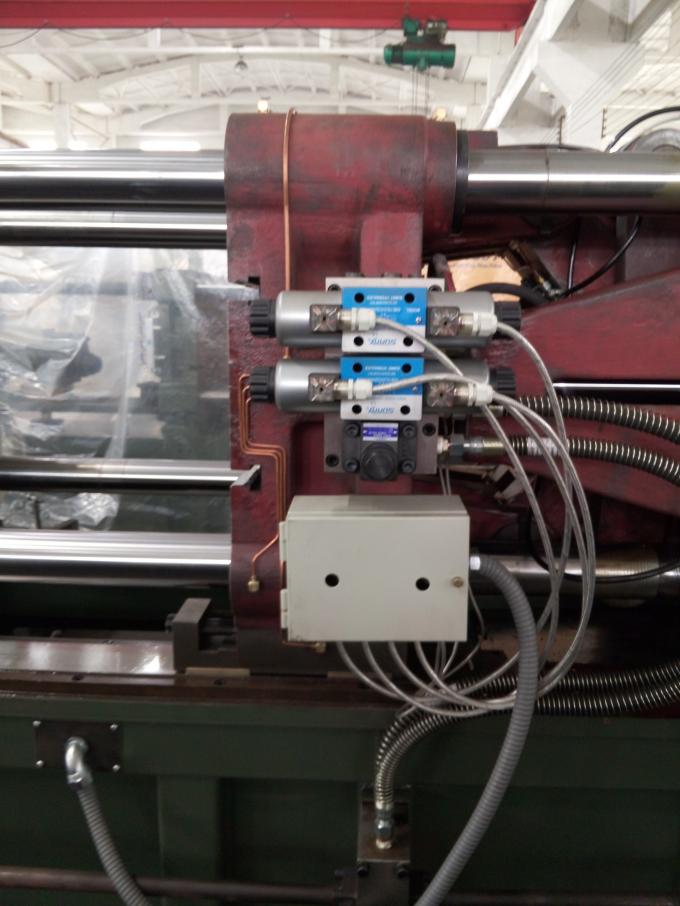

Four stages control of injection speed and pressure, independent high-speeding intensification injection accumulators. Quality accumulator in die casting machine insure the pressure output stable, strong, fast. Two intensification activation ways: position way and pressure way.

-

Mould platens and Tie bars

High rigidity molding platen, high tensile alloy steel hard chrome plated tie bar.

-

PLC System

PLC control system (with touch screen) with fast, stable, safe and reliable operation, high precision, and functions such as production management, trouble diagnosis, and 50 sets mould parameters storage.

-

High speed hydraulic ejection and core-pulling devices.

-

Electrical proportional control of system pressure and flow, with multi-stage pressure and speed control, and low-pressure die close protection function.

More information about 300T Pressure Die Casting Machine cost and Service, Please email us: cnkylt@aliyun.com

Related Casting Machinery:

Die Casting Machine

· Battery Spine Die Casting Machine

· Cold Chamber Die Casting Machine

· Hot Chamber Die Casting Machine

· Vertical Die Casting Machine

· PDC casting machine

Material

· Aluminum Die Casting Machine

· Magnesium Die Casting Machine

· Copper Die Casting Machine

· Zinc Die Casting Machine

· Lead Die Casting Machine

Application

· Auto Parts Die Casting Machines

· Kitchen &Household Parts Die Casting Machines

· Lamps Light Parts Die Casting Machines

· Electric Vehicle Spare Parts Die Casting Machines

· Hardware, Jewelry, Clothing Accessories Die Casting Machines

· Tel-Communication Equipment Parts Die Casting Machines

· Garden Machinery & Electric Tools Parts Die Casting Machines

· Lead Acid Battery Terminal Bushing, Battery Positive Spine Grid Die Casting Machines

· Fishing Sinker Die Casting Machines

· Others