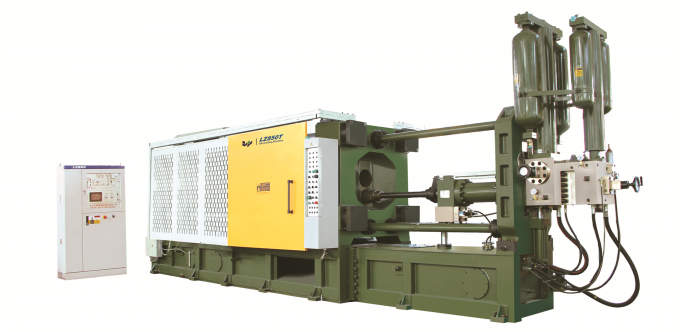

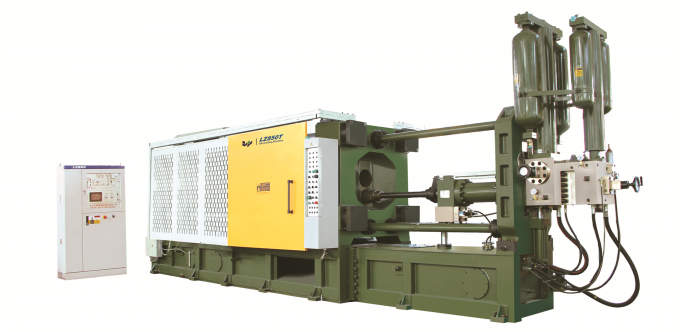

850T Cold Chamber Pressure Die Casting Machine Specification (LZ850T)

| No. |

ITEM |

UNIT |

LZ850 |

| 1 |

Clamping Force |

KN |

8500 |

| 2 |

Inner space between tie bars(H*V) |

mm |

920×920 |

| 3 |

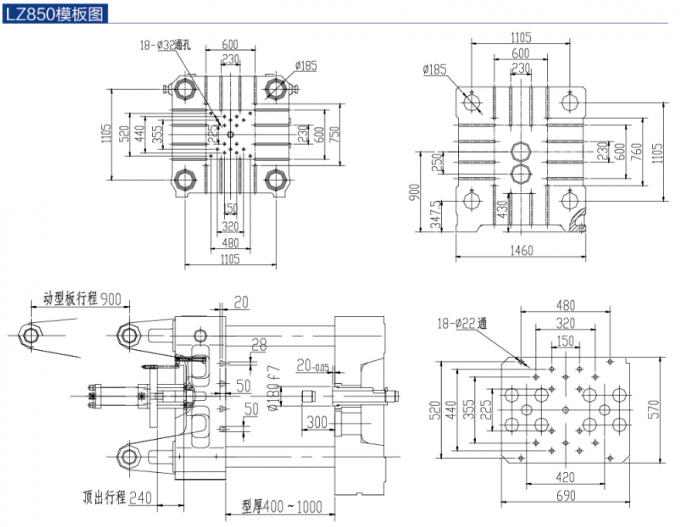

Die Stroke |

mm |

900 |

| 4 |

Die Thickness |

mm |

400~1000 |

| 5 |

Ejection Stroke |

mm |

240 |

| 6 |

Ejection Force |

KN |

400 |

| 7 |

Injeciton Force |

KN |

280~750 |

| 8 |

Injection position(center is "0",down is "-") |

mm |

0,-250 |

| 9 |

Dia. of shot sleeve |

mm |

80,60,100,110,120 |

| 10 |

Dia.of Injection chamber flange |

mm |

180f7 |

| 11 |

Over height of flange |

mm |

20-0.05 |

| 12 |

Dosage of fluid metal pershot |

kg |

16(Al.) |

| 13 |

Projected area |

cm |

570~3400 |

| 14 |

Injection pressure |

Mpa |

68~149 |

| 15 |

Dry cycle |

s |

14 |

| 16 |

Oil tank capacity |

L |

1600 |

| 17 |

Motor power |

KW |

45 |

| 18 |

Machine sizes(L*W*H) |

M |

10.5×2.4×3.4 |

(Remark: 1.The die casting machine supplier keeps the right to revise above parameters, If there is any alterations, advance notice won't be given then. 2. Servo die casting machine can be choosed to save energy and cost. )

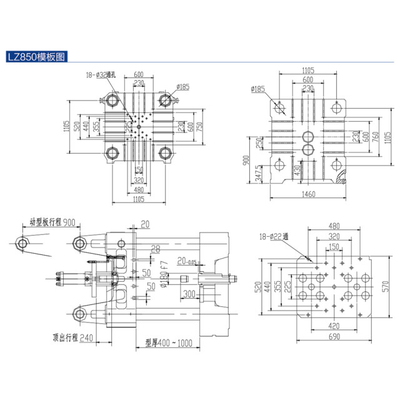

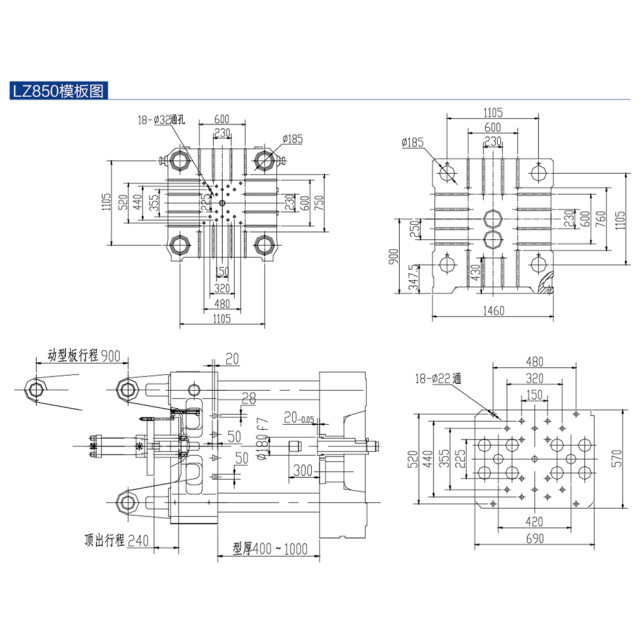

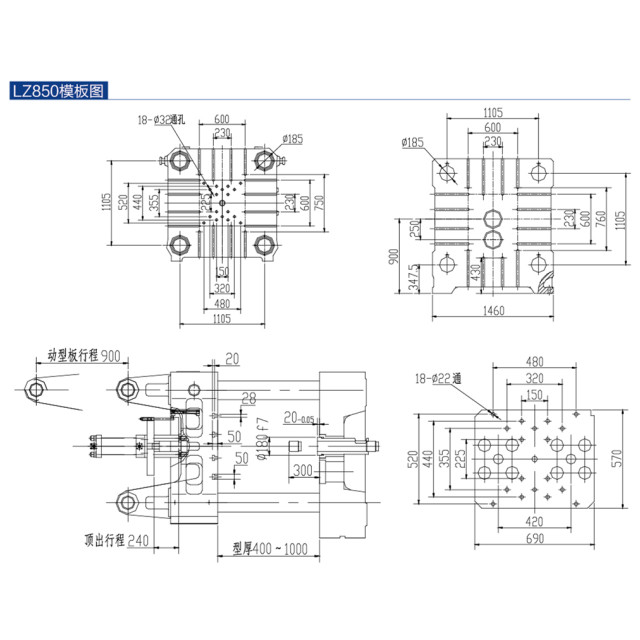

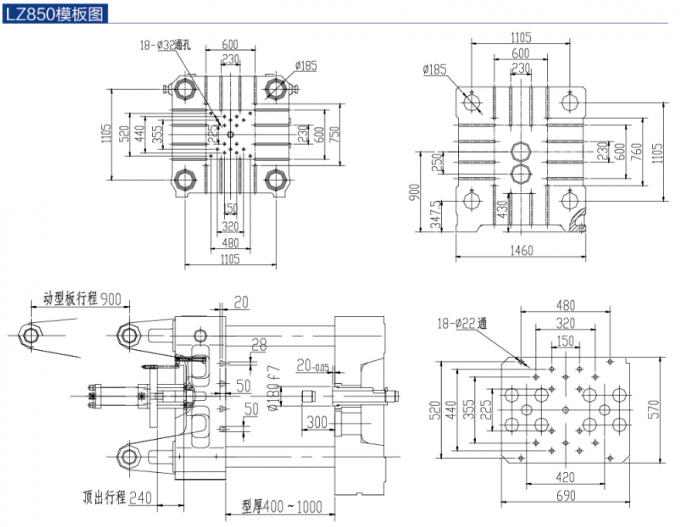

850T Cold Chamber Pressure Die Casting Machine Molding Plate Specification:

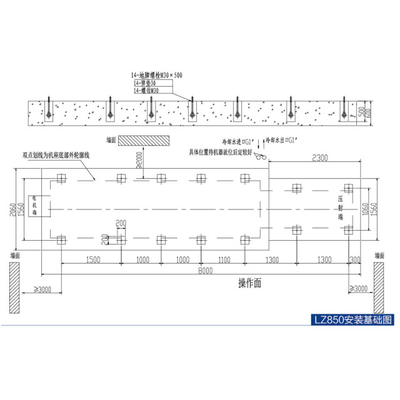

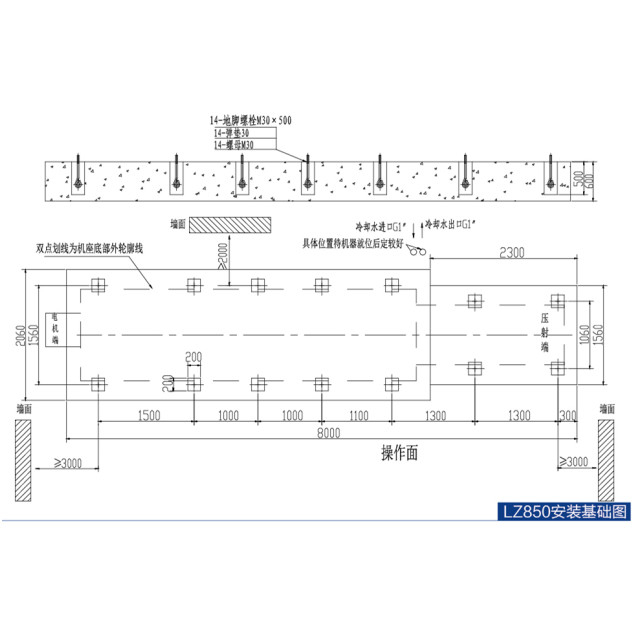

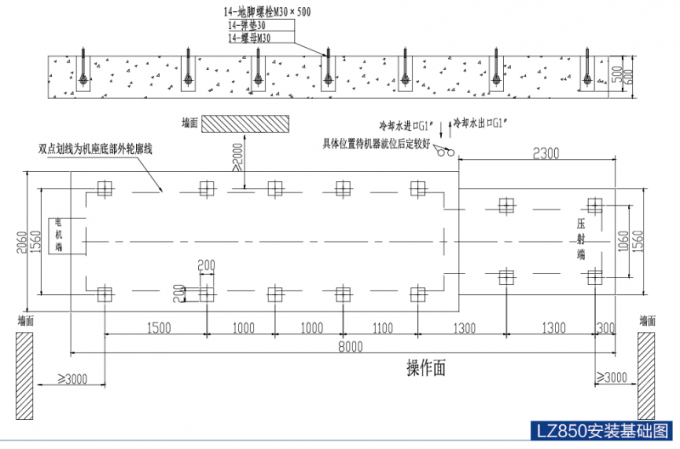

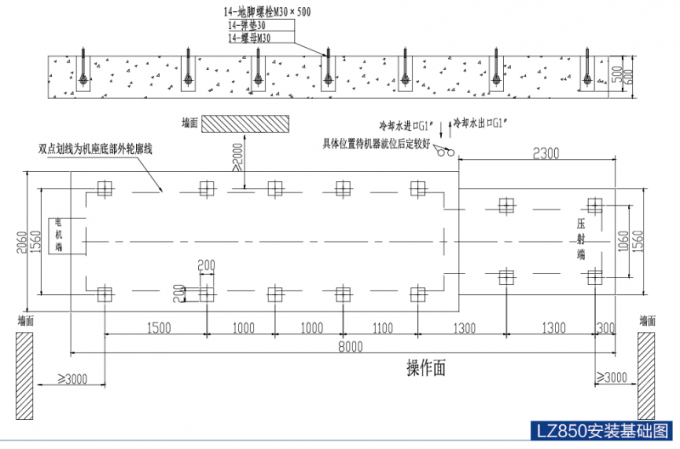

850T Cold Chamber Pressure Die Casting Machine Cement Ground Specification:

HOW DOES A HORIZONTAL COLD CHAMBER DIE-CAST MACHINE ACHIEVE AUTOMATIC DIE CAST PROCESS?

Withour the support of Auxiliary equipment, Horizontal Cold Chamber High Pressure Die Casting Machine works with Maunual method.

In large scale die casting process, die cast parts weight are heavy, need tools or machines support. That require use auxiliary machines or robots. Or, use auxiliary machines to save labor cost for small tonnage die cast machines.

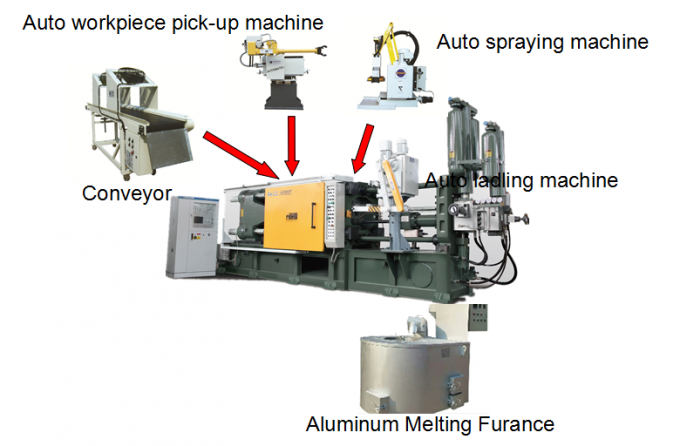

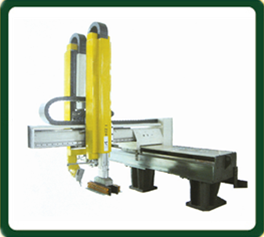

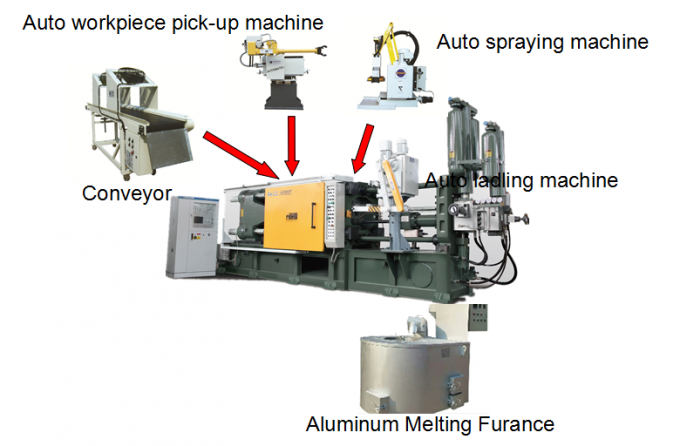

Full Automation horizontal cold chamber die-casting machines auxiliary equipment:

The use of auxiliary equipment makes the whole die cast process automatically.

Above photo shows the whole automatic die casting unit. It consists of: Alloy Melting furance, Auto ladling machine, PLC Die casting machine, Auto spraying machine, Extractor(Auto die cast parts pick-up robot).

Auxiliary equipments connect with PLC die casting machine, all machines work are programmed and controlled by PLC.

1. Metal Alloy Melting furance

-Melting furance usages: used to melt Aluminum, Zinc, Copper alloy.

-Melting furance types: Electric melting furnace, Gas melting furance, Biological particales melting furance.

(For magnesium alloy die casting, special Magnesium alloy automatic pouring melting furance must be used.)

Die casting machine melting pot types:

- Graphite crucible for die casting machine melting kettle, it is popular in die casting process now.

- Cast iron crucibe for pressure die-cast machine melting pot.

2. Auto ladling machine/robot

Automatic ladling machine or robot ladles molten metal alloy from furnace pot to die casting machine cold chamber.

3. PLC Die casting machine

Programable PLC touch screen used to set machines actions.

4. Auto spraying machine

Automatic sprayer robot used to clean, lubricate and cool the mold cavities.

-Automatic spraying machine for small die casting machine

-Automatic spraying machine for large die casting machine

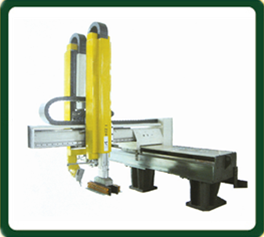

5. Extractor(Auto die cast parts pick-up robot)

Auto die casting parts pick-up machine or robot also named Extractor, which used to take die cast parts out from mold to working tale or conveyor belt.

6. Conveyor Belt

Conveyor Belt can be choosed to transport die casting parts.

7. other equipment

Of course, stamping machine can be used to cut flash or burr, Picking up machine is used to move the die casting parts from mold to stamping machine tool directly.

Full automatic die casting machine working process:

Full automatic working process: Die casting machine PLC control the whole process. Automatic ladler pour molten aluminum metal alloy from melting pot to die casting machine cold chamber. Then, be inject to mold cavities to got die-cast parts. Auto extractor pick-up casting part from die tool, put them on conveyor. The auto sprayer cooling and lubricating the mold cavity. And, to start then next die casting process.

How to choose suitable cold chamber die casting machine?

1.As per different die casting metal alloy, die caster types: aluminum die casting machine, zinc (zamak) die casting machine, magneisum die casting machine, copper (brass) die casting machine.

- Aluminum die casting machine used to produce aluminum alloy die casting parts. Use a gas or electric melting furance can start the production. Die casting mould normally is H13 mold steel.

- Zinc/Zamak die casting machine, in cold chamber types, it used to produce big zinc alloy die casting parts. (For small die casting parts, such as zipper slider, jewelry, electronic part, hot chamber die casting machine is more suitable.) Same as Aluminum die casting, just has an extra melting pot can start produce zamak die casting parts.

- Magnesium die casting machine. Magnesium alloy characters strong, light weight, easy for machining. It is more popular those years. To produce magnesium die casting part, specail ordered magnesium die casting machine with a magneisum alloy melting furance must be used. The furance connect with protect gas, avoid buring in melting process, quantitative feeding magnesium alloy to pressure machine cold chamber.

2. As per die casting machine tonnage, it can be classifed as: small die casting machine, large scale die casting mahcine.

Small die casting machine most is hot chamber high pressure injection machine. It has horizontal type and vertical type.

Large scale die casting machine normally is cold chamber pressure die-cast machine. Most is horizontal type.

Servo driven die casting machine diagram:

More information and price list of 850T Cold Chamber Pressure Die Casting Machine,Alloy Melting furance, Auto ladling machine, Auto spraying machine, Extractor(Auto die cast parts pick-up robot) and Services, Please email us: cnkylt@aliyun.com.

Related Casting Machinery:

Die Casting Machine

· Battery Spine Die Casting Machine

· Cold Chamber Die Casting Machine

· Hot Chamber Die Casting Machine

· Vertical Die Casting Machine

· PDC casting machine

Material

· Aluminum Die Casting Machine

· Magnesium Die Casting Machine

· Copper Die Casting Machine

· Zinc Die Casting Machine

· Lead Die Casting Machine

Application

· Auto Parts Die Casting Machines

· Kitchen &Household Parts Die Casting Machines

· Lamps Light Parts Die Casting Machines

· Electric Vehicle Spare Parts Die Casting Machines

· Hardware, Jewelry, Clothing Accessories Die Casting Machines

· Tel-Communication Equipment Parts Die Casting Machines

· Garden Machinery & Electric Tools Parts Die Casting Machines

· Lead Acid Battery Terminal Bushing, Battery Positive Spine Grid Die Casting Machines

· Fishing Sinker Die Casting Machines

· Others