Are you interested in learning more about the die casting machine used for Aluminum alloy, Zinc/ZAMAK alloy lamp or light spare parts? This article will provide an in-depth overview of this process and the machine used to produce high-quality, durable parts.

Introduction

Die casting is a popular manufacturing process used to produce complex and precise parts in high volumes. It involves injecting molten metal into a mold cavity at high pressure, which then solidifies to form the desired part. Aluminum, Zinc, and ZAMAK alloys are commonly used in die casting, as they offer excellent strength, durability, and corrosion resistance.

(Zinc/ZAMAK alloy car lamp heat radiation parts )

The Die Casting Machine Used for Aluminum Alloy, Zinc/ZAMAK Alloy Lamp or Light Spare Parts

The die casting machine used for Aluminum alloy, Zinc/ZAMAK alloy lamp or light spare parts is a specialized piece of equipment designed to handle the unique properties of these metals. It typically consists of two major components: the injection system and the clamping system.

The Injection System

The injection system is responsible for melting the metal and injecting it into the mold cavity. It consists of several key components, including the melting furnace, the shot chamber, and the plunger.

The melting furnace is where the raw metal is heated to its melting point. Once it has reached the appropriate temperature, it is transferred to the shot chamber, which is a cylinder that holds the molten metal. The plunger then pushes the metal from the shot chamber into the mold cavity at high pressure.

The Clamping System

The clamping system is responsible for holding the mold in place and applying the necessary pressure to ensure that the part is formed correctly. It consists of several key components, including the mold, the clamping unit, and the ejector system.

The mold is the component that shapes the metal into the desired part. It is typically made from steel and can be custom-designed to produce parts with complex geometries. The clamping unit holds the mold in place and applies the necessary pressure to ensure that the metal fills the mold completely. Once the part has solidified, the ejector system removes it from the mold.

Die casting machine for Aluminum Zinc/Zamak Lamp Light Parts. That is Aluminum/Zinc Cold Chamber Die Casting Machine used to produce all kinds of lamps and spare parts. Such as: Wall lamp, post/street lamp, pillar lamp, bollard lamp, Courtyard lamp, Floor lamp, Landscape lamp, lamps and lanterns etc. Many lamps & parts are made by aluminum die casting.

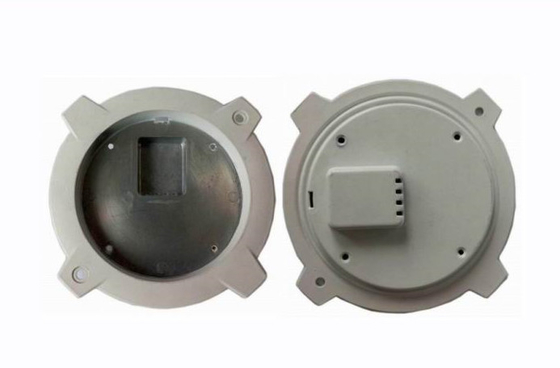

Aluminum Die casting lamp/light parts involve: lamp holder, lamp shade, Lamp housing, lamp shell, lamp cover, LED heatsink, LED light base etc.

Zinc/Zamak die casting lamp/light parts most used in desk lamp. The base of table lamp or reading lamp are made Zinc/Zamak alloy. Zinc alloy is heavy, it works as a weight part to keep the desk lamp stable. Of course, outdoor Lamp holder etc parts also can be made from zinc alloy depends on design.

Advantages of Die Casting Machine Used for Aluminum Alloy, Zinc/ZAMAK Alloy Lamp or Light Spare Parts

There are several advantages to using a die casting machine for aluminum alloy, zinc/ZAMAK alloy lamp or light spare parts. These include:

-

High production efficiency: Die casting allows for the production of large volumes of parts quickly and efficiently.

-

Consistent quality: The precision of the die casting process ensures that each part is of the same high quality.

-

Design flexibility: The mold can be customized to produce parts with complex geometries and fine details.

-

Durability: Aluminum, Zinc, and ZAMAK alloys are known for their strength, durability, and corrosion resistance, making them ideal for lamp or light spare parts.

Conclusion

The die casting machine used for Aluminum alloy, Zinc/ZAMAK alloy lamp or light spare parts is a specialized piece of equipment that allows for the production of high-quality, precise parts in large volumes. By understanding the key components and advantages of this process, manufacturers can produce lamp or light spare parts that meet the highest standards of quality and durability.

If you're interested in producing lamp or light spare parts using a die casting machine, it's important to work with a reliable and experienced supplier who can help you select the right equipment and ensure the success of your production process.

Thank you for reading! We hope this article has been helpful in providing an overview of the die casting machine used for Aluminum alloy, Zinc/ZAMAK alloy lamp or light spare parts.

KYLT Industrial is one of Lmp Light Aluminum/Zinc/Zamak Die casting machines manufacturer & supplier & factory in china. Also provide Aluminum/Zinc/Zamak Alloy lamp light die casting mould and die casting parts making service.

Get a FREE quotation of your Lamp light parts making die casting machines price, Lamp light die casting parts price, Lamp light spare parts die casting mould/mold/die price, please email: cnkylt@aliyun.com

FAQs

-

What is the difference between aluminum, zinc, and ZAMAK alloys?

Aluminum is a lightweight, corrosion-resistant metal that is ideal for use in applications where weight is a concern. Zinc is a denser, more durable metal that is often used in applications where strength is a priority. ZAMAK is a zinc alloy that also contains aluminum, magnesium, and copper, and is known for its excellent castability and dimensional stability.

-

What types of lamp or light spare parts can be produced using a die casting machine?

A die casting machine can be used to produce a wide range of lamp or light spare parts, including lamp bases, lamp housings, light fittings, and more.

-

What is the typical production volume for die casting lamp or light spare parts?

Die casting allows for the production of high volumes of parts, making it an ideal process for lamp or light spare parts. The exact production volume will depend on factors such as the size and complexity of the part, but die casting machines can typically produce hundreds or thousands of parts per hour.

-

How does die casting compare to other manufacturing processes for lamp or light spare parts?

Compared to other manufacturing processes, such as machining or injection molding, die casting offers several advantages. It allows for the production of complex parts with high precision, and can produce parts in large volumes quickly and efficiently.

-

What are some common applications of die casting lamp or light spare parts?

Die casting lamp or light spare parts are commonly used in a wide range of applications, including residential and commercial lighting fixtures, automotive lighting, and streetlights.

-

What factors should be considered when selecting a die casting machine for lamp or light spare parts production?

When selecting a die casting machine for lamp or light spare parts production, several factors should be considered, such as the size and complexity of the parts, the desired production volume, and the specific properties of the metal alloy being used.

Related Metal Casting Machinery:

Die Casting Machines Types:

· Battery Spine Die Casting Machine

· Cold Chamber Die Casting Machine

· Hot Chamber Die Casting Machine

· Vertical Die Casting Machine

· PDC casting machine

Die Casting Machines Classification by Materials:

· Aluminum Die Casting Machine

· Magnesium Die Casting Machine

· Copper Die Casting Machine

· Zinc Die Casting Machine

· Lead Die Casting Machine

Die Casting Machines Application:

· Auto Parts Die Casting Machines

· Kitchen &Household Parts Die Casting Machines

· Lamps Light Parts Die Casting Machines

· Electric Vehicle Spare Parts Die Casting Machines

· Hardware, Jewelry, Clothing Accessories Die Casting Machines

· Tel-Communication Equipment Parts Die Casting Machines

· Garden Machinery & Electric Tools Parts Die Casting Machines

· Lead Acid Battery Terminal Bushing, Battery Positive Spine Grid Die Casting Machines

· Fishing Sinker Die Casting Machines

· Other