As the world continues to move towards renewable energy and environmentally friendly transportation, electric vehicles (EVs) are becoming more popular. The demand for die casting aluminum or zinc alloy parts used in electric vehicles has skyrocketed in recent years. These parts are crucial for the performance, efficiency, and safety of EVs. In this article, we’ll delve into the details of die casting aluminum or zinc alloy parts used in electric vehicles.

Introduction

Electric vehicles have revolutionized the automotive industry with their eco-friendly technology. These vehicles are powered by electricity stored in rechargeable batteries, eliminating the need for fossil fuels. The popularity of electric vehicles has led to an increase in demand for die casting aluminum or zinc alloy parts used in electric vehicles. These parts are used in various components of electric vehicles such as the motor, battery casing, and powertrain.

What is Die Casting?

Die casting is a manufacturing process used to produce metal parts with high precision and accuracy. The process involves injecting molten metal into a mold cavity, which is then cooled and solidified. The mold is then opened, and the part is ejected. The die casting process is widely used to produce complex shapes and parts with high dimensional accuracy.

Die Casting Aluminum or Zinc Alloy Parts Used in Electric Vehicle

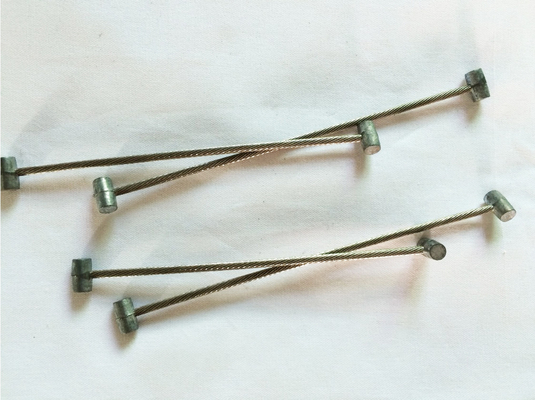

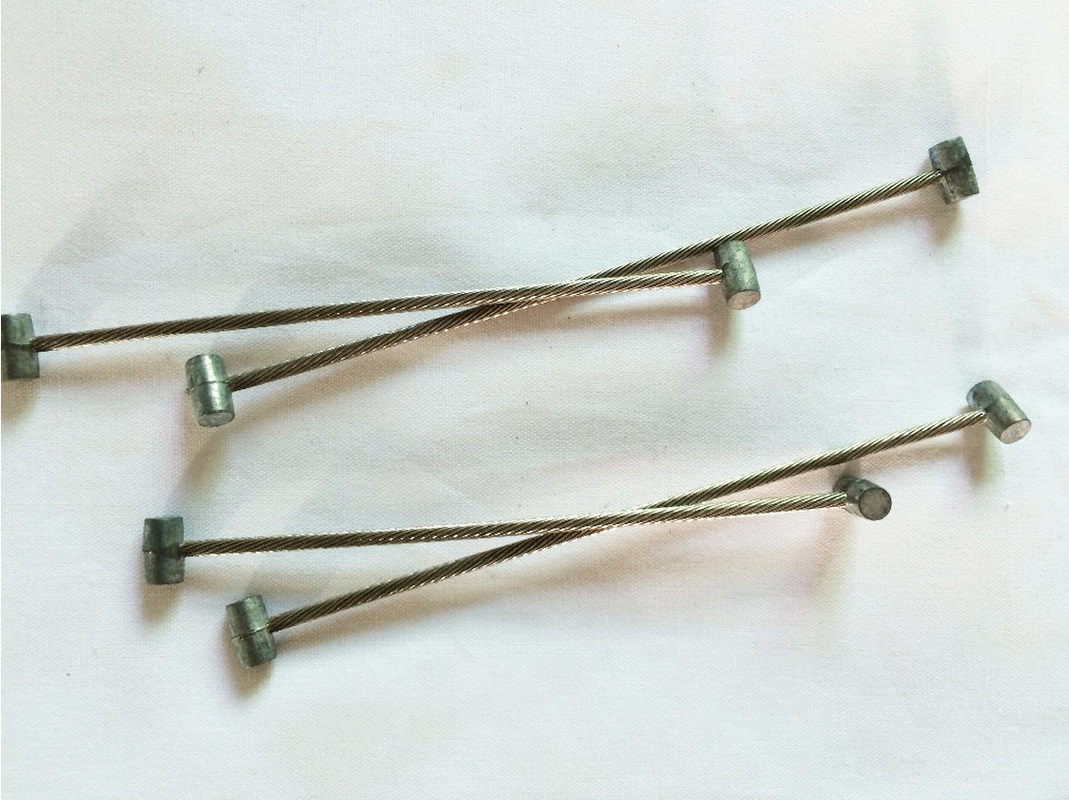

The die casting process is commonly used to produce aluminum die casting parts or Zamak/Zinc alloy die-cast parts used in electric vehicles. These parts are used in various components of electric vehicles such as:

BATTERY CASING

The battery casing is an essential component of an electric vehicle. It houses the rechargeable battery that powers the vehicle. Die casting is used to produce lightweight and durable aluminum or zinc alloy battery casings that provide protection to the battery.

MOTOR HOUSING

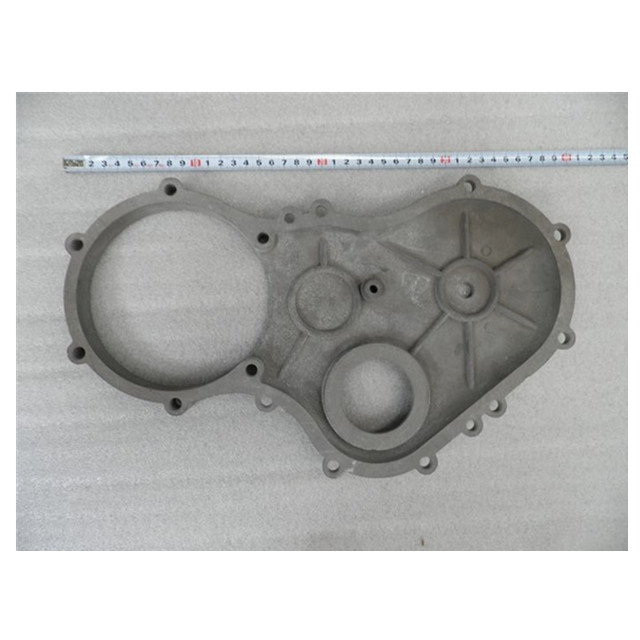

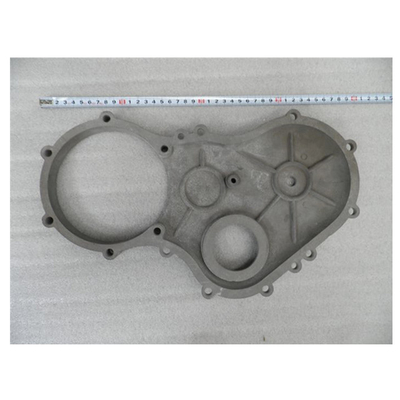

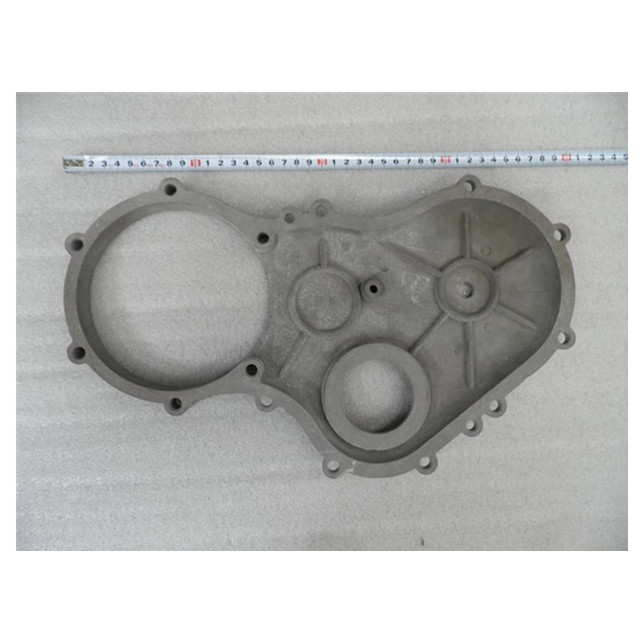

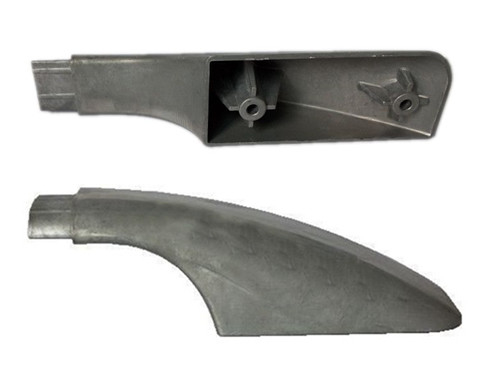

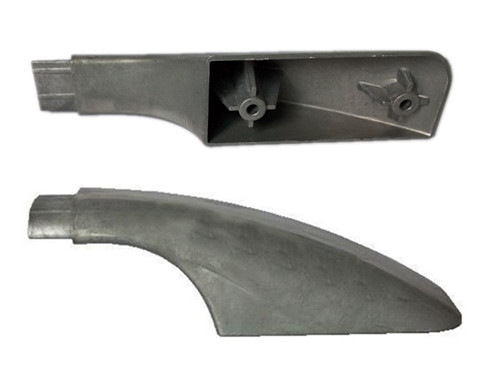

The electric motor is the heart of an electric vehicle. It converts electrical energy into mechanical energy that drives the wheels of the vehicle. Die casting is used to produce lightweight and strong aluminum or zinc alloy motor housings that protect the motor and provide efficient heat dissipation.

POWERTRAIN COMPONENTS

The powertrain is a critical component of an electric vehicle. It includes the motor, transmission, and drivetrain. Die casting is used to produce lightweight and high-strength aluminum or zinc alloy components for the powertrain, such as transmission cases and differential housings.

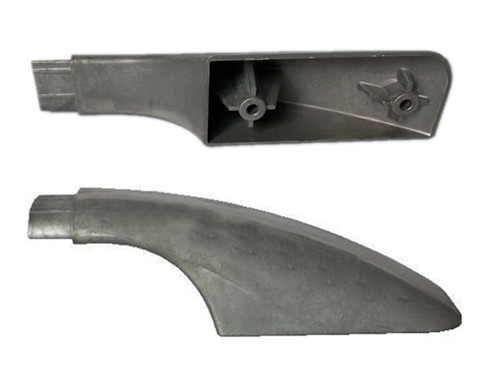

OTHER COMPONENTS

Apart from battery casing, motor housing, and powertrain components, die casting is used to produce several other components used in electric vehicles, such as suspension parts, steering components, and brake components.

Advantages of Using Die Casting Aluminum or Zinc Alloy Parts in Electric Vehicles

Die casting aluminum or zinc alloy parts used in electric vehicles offer several advantages, such as:

LIGHTWEIGHT

Die casting produces lightweight parts that help reduce the overall weight of the vehicle, improving its energy efficiency and range.

HIGH STRENGTH

Aluminum and zinc alloy parts produced by die casting are strong and durable, providing superior performance and reliability.

HIGH PRECISION

Die casting produces parts with high dimensional accuracy and precision, ensuring tight tolerances and excellent fit and function.

COST-EFFECTIVE

Die casting is a cost-effective manufacturing process that produces high-quality parts at a lower cost compared to other manufacturing processes.

Conclusion

The demand for electric vehicles is growing rapidly, and so is the demand for die casting aluminum or zinc alloy parts used in electric vehicles. These parts offer several advantages, such as lightweight, high strength, high precision, and cost-effectiveness. Die casting is a sustainable manufacturing process that produces high-quality parts at a lower cost compared to other manufacturing processes. As the world moves towards sustainable transportation, die casting aluminum or zinc alloy parts will play a crucial role in the development of electric vehicles.

In conclusion, die casting aluminum or zinc alloy parts used in electric vehicles are essential components that contribute to the performance, efficiency, and safety of electric vehicles. As the demand for electric vehicles continues to rise, the demand for die casting aluminum or zinc alloy parts will also increase. The future of sustainable transportation is bright, and die casting is at the forefront of this revolution.

Get a FREE quotation of your Electric Vehicle Aluminum Zinc (ZAMAK) die casting parts price, Aluminum ZAMAK Zinc die casting mould/mold/die price, please email: cnkylt@aliyun.com

Frequently Asked Questions

Q1. WHAT IS THE DIFFERENCE BETWEEN ALUMINUM AND ZINC ALLOY DIE CASTING?

A1. Aluminum and zinc alloy die casting processes use different types of metals. Aluminum is lightweight and offers excellent corrosion resistance, while zinc is less expensive and offers excellent castability.

Q2. WHAT ARE THE ADVANTAGES OF USING ALUMINUM OVER ZINC FOR DIE CASTING ELECTRIC VEHICLE PARTS?

A2. Aluminum is lighter than zinc, providing better energy efficiency and range. It also offers superior corrosion resistance, making it ideal for parts exposed to harsh environmental conditions.

Q3. HOW DOES THE USE OF DIE CASTING ALUMINUM OR ZINC ALLOY PARTS AFFECT THE PERFORMANCE OF AN ELECTRIC VEHICLE?

A3. Die casting aluminum or zinc alloy parts offer superior performance and reliability, as they are strong and durable, and have excellent dimensional accuracy and precision.

Q4. CAN DIE CASTING BE USED TO PRODUCE PARTS FOR HYBRID VEHICLES AS WELL?

A4. Yes, die casting can be used to produce parts for hybrid vehicles as well. Hybrid vehicles use a combination of an internal combustion engine and an electric motor, and die casting can be used to produce parts for both.

Q5. IS DIE CASTING A SUSTAINABLE MANUFACTURING PROCESS?

A5. Yes, die casting is a sustainable manufacturing process. It produces very little waste and can be recycled, making it an eco-friendly and sustainable manufacturing process.

Q6. ARE DIE CASTING ALUMINUM OR ZINC ALLOY PARTS USED ONLY IN ELECTRIC VEHICLES, OR ARE THEY USED IN OTHER APPLICATIONS AS WELL?

A6. Die casting aluminum or zinc alloy parts are used in various applications other than electric vehicles, such as aerospace, consumer electronics, medical devices, and more. Die casting is a versatile manufacturing process that can be used to produce parts for a wide range of applications.

KYLT CNC Machining Services:

Home>CNC Machining Services>CNC Milling Services

Home>CNC Machining Services>CNC Turning Services

Home>CNC Machining Services>Rapid Prototyping Services

Home>CNC Machining Services>Injection Molding Services

KYLT CNC Precision Machined Parts:

Home>Precision CNC Machined Parts

Home>Precision CNC Machined Parts>CNC Precise Turned Parts

Home>Precision CNC Machined Parts>CNC Precise Milled Parts

Home>Precision CNC Machined Parts>Aluminum Machining

Home>Precision CNC Machined Parts>Magnesium Machining

Home>Precision CNC Machined Parts>Copper & Brass Machining

Home>Precision CNC Machined Parts>Steel Machining

Home>Precision CNC Machined Parts>Stainless Steel Machining

Home>Precision CNC Machined Parts>Plastic Machining

More information about Machining Technology: