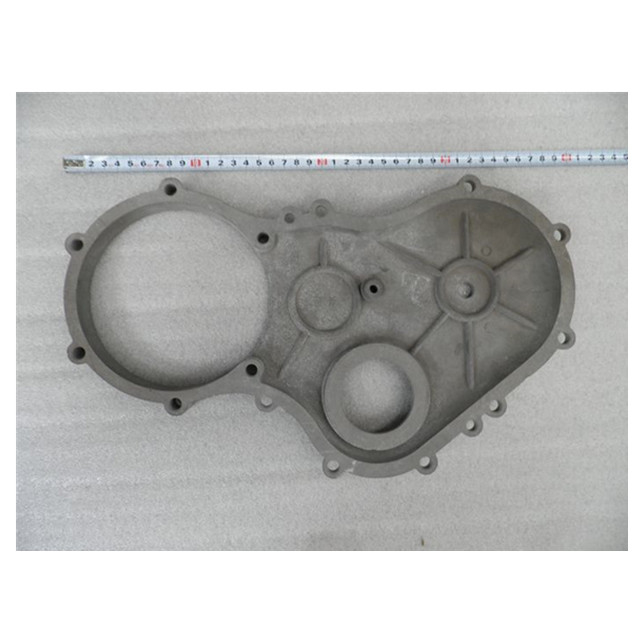

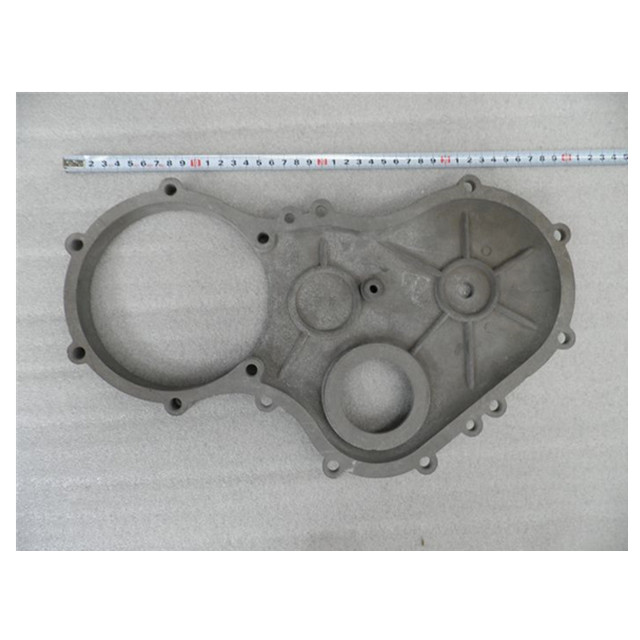

Aluminum die casting is a manufacturing process that involves the injection of molten aluminum into a die or mold under high pressure. The molten aluminum fills the cavity of the die and takes its shape, then solidifies and cools to form a precise, high-quality part. The Aluminum die casting machines are the key machinery to produce aluminum die casting parts.

Why is Aluminum Die Casting Popular?

Aluminum die casting is a popular manufacturing process for a variety of reasons:

LIGHTWEIGHT AND DURABLE

Aluminum is a lightweight, yet durable material that is resistant to corrosion and has a high strength-to-weight ratio. These properties make it an ideal material for a wide range of applications.

VERSATILE AND COST-EFFECTIVE

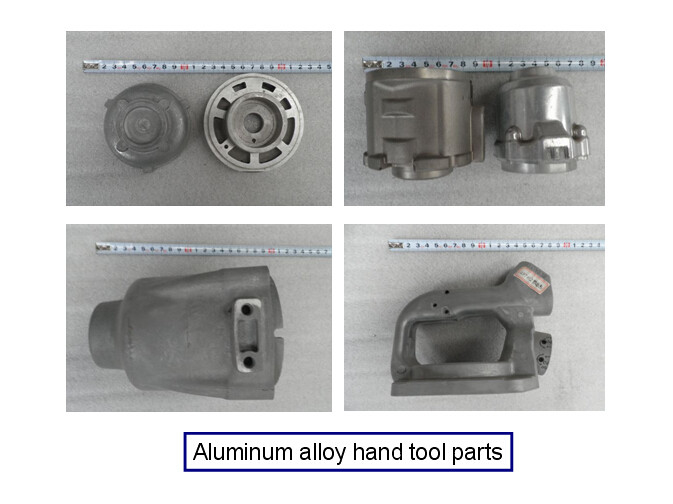

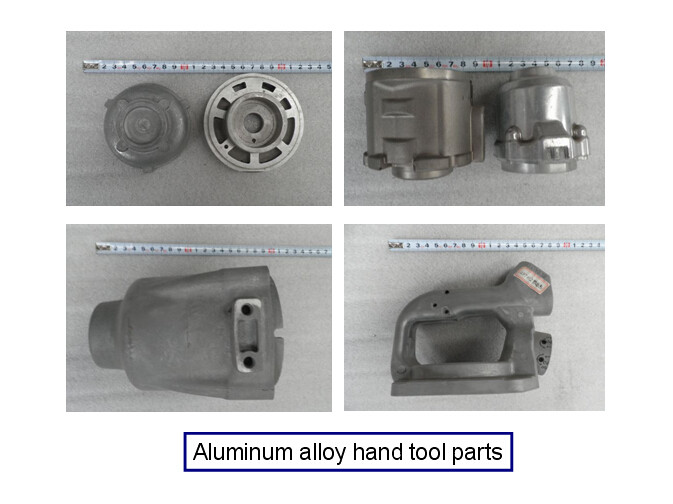

Aluminum die casting is a versatile manufacturing process that can be used to produce a wide range of complex shapes and designs. It is also a cost-effective manufacturing process, as it requires minimal machining and finishing after the part is cast.

HIGH-QUALITY PARTS

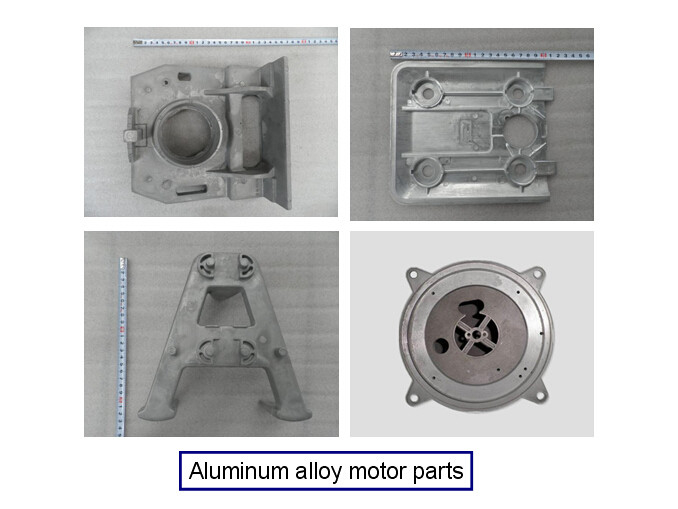

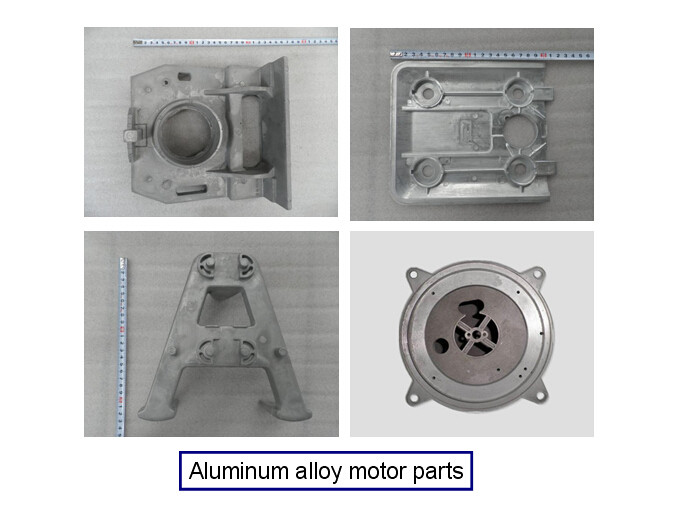

Aluminum die casting produces high-quality parts that are accurate, consistent, and have a high level of detail. The process produces parts with tight tolerances, smooth surfaces, and excellent mechanical properties.

How Does Aluminum Die Casting Work?

Aluminum die casting involves several steps:

MOLD PREPARATION

The die or mold is prepared by cleaning and lubricating it to ensure the molten aluminum flows smoothly into the cavity. (Aluminum die casting mould/mold/die making service: cnkylt@aliyun.com)

INJECTION OF MOLTEN ALUMINUM

The molten aluminum is injected into the die at high pressure, filling the cavity and taking its shape. The pressure is maintained until the aluminum solidifies.

COOLING AND EJECTION

After the aluminum solidifies, the die is opened and the part is ejected. The part is then cleaned, trimmed, and finished as required.

Aluminum alloy die casting parts & die casting mould/mold/die making service: cnkylt@aliyun.com

What are the Advantages of Aluminum Die Casting?

Aluminum die casting offers several advantages over other manufacturing processes:

FAST PRODUCTION

Aluminum die casting is a fast production process that can produce high volumes of parts in a short amount of time.

CONSISTENT QUALITY

The process produces consistent, high-quality parts that meet tight tolerances and have excellent mechanical properties.

DESIGN FLEXIBILITY

Aluminum die casting offers a high degree of design flexibility, allowing for complex shapes and designs to be produced with precision and accuracy.

COST-EFFECTIVE

Aluminum die casting is a cost-effective manufacturing process, as it requires minimal machining and finishing after the part is cast.

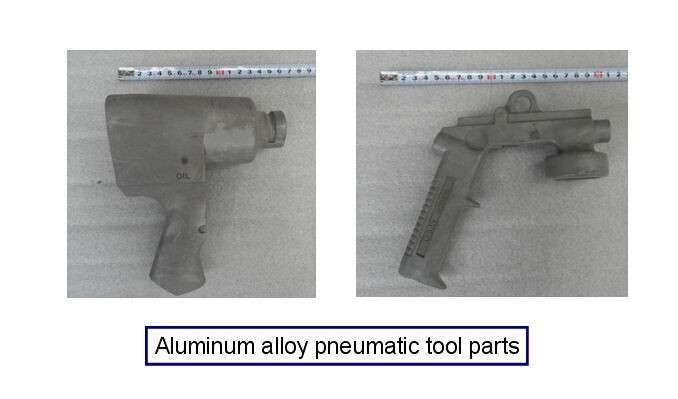

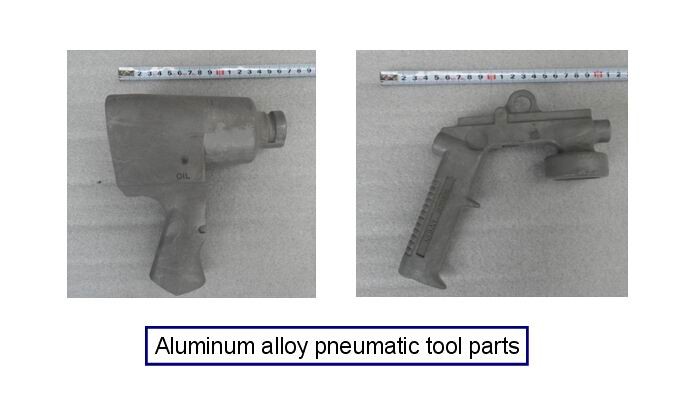

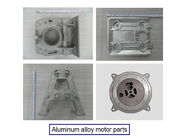

What are the Applications of Aluminum Die Casting?

Aluminum die casting is used in a wide range of applications, including:

AUTOMOTIVE PARTS

Aluminum die casting is used to produce automotive parts such as engine blocks, cylinder heads, and transmission housings.

CONSUMER GOODS

Aluminum die casting is used to produce consumer goods such as cookware, electronics, and sporting equipment.

AEROSPACE

Aluminum die casting is used to produce aerospace parts such as structural components and engine parts.

ELECTRIC DEVICES

Aluminum die casting is used to produce electric devices such as electric boxes and heat radiation.

What are the Limitations of Aluminum Die Casting?

Aluminum die casting has some limitations, including:

PART SIZE

Aluminum die casting is limited in the size of parts that can be produced. Large parts may require a different manufacturing process.

TOOLING COSTS

The cost of tooling can be high for aluminum die casting, particularly for complex parts.

SURFACE FINISH

The surface finish of aluminum die cast parts may require additional machining or finishing to achieve the desired result.

Conclusion

Aluminum die casting is a versatile, cost-effective, and high-quality manufacturing process that produces complex shapes and designs with precision and accuracy. It offers a range of advantages over other manufacturing processes and is used in a wide range of applications across various industries.

More KYLT Aluminum die casting, Machining Services & Products Information:

Visit CNC Milling Parts, EDM/WEDM Parts , CNC Machining Service, Rapid Prototype for your reference.

To get more information about KYLT products and services, please e-mail to cnkylt@aliyun.com to get a FREE quote.

KYLT Precision CNC machining services (milling & turning service), Fast prototyping, Fixture/Jig/Tooling making, Aluminum die casting & plastic injection parts. Email:cnkylt@aliyun.com

FAQs

- What is the difference between aluminum die casting and aluminum extrusion?

- What are the advantages of using aluminum in die casting?

- How does the quality of aluminum die casting compare to other manufacturing processes?

- Can aluminum die casting be used for large parts?

- What industries commonly use aluminum die casting for their manufacturing needs?

WHAT IS THE DIFFERENCE BETWEEN ALUMINUM DIE CASTING AND ALUMINUM EXTRUSION?

Aluminum die casting and aluminum extrusion are both manufacturing processes that involve the use of aluminum. However, the processes are different in several ways.

Aluminum die casting involves injecting molten aluminum into a die or mold at high pressure, while aluminum extrusion involves pushing heated aluminum through a die to create a continuous profile. Die casting produces more complex shapes and designs with high accuracy, while extrusion is better suited for producing continuous profiles such as tubing or rods.

WHAT ARE THE ADVANTAGES OF USING ALUMINUM IN DIE CASTING?

Aluminum is a popular material for die casting for several reasons. It is lightweight, yet durable, with excellent corrosion resistance and a high strength-to-weight ratio. Aluminum also has good thermal conductivity, which makes it an ideal material for applications that involve heat transfer.

HOW DOES THE QUALITY OF ALUMINUM DIE CASTING COMPARE TO OTHER MANUFACTURING PROCESSES?

Aluminum die casting produces high-quality parts that are accurate, consistent, and have a high level of detail. The process produces parts with tight tolerances, smooth surfaces, and excellent mechanical properties. Compared to other manufacturing processes such as injection molding or stamping, die casting offers greater design flexibility and produces parts with higher strength and durability.

CAN ALUMINUM DIE CASTING BE USED FOR LARGE PARTS?

Aluminum die casting is generally suited for small to medium-sized parts. While it is possible to produce larger parts using die casting, the size of the die and the pressure required to fill the cavity limit the size of the parts that can be produced. For larger parts, other manufacturing processes such as sand casting or forging may be more suitable.

WHAT INDUSTRIES COMMONLY USE ALUMINUM DIE CASTING FOR THEIR MANUFACTURING NEEDS?

Aluminum die casting is used in a wide range of industries, including automotive, aerospace, consumer goods, and medical devices. It is particularly popular for applications that require lightweight, high-strength parts with complex shapes and designs. Some common examples of products produced using aluminum die casting include engine blocks, transmission housings, and electronic enclosures.

KYLT CNC Machining Services:

Home>CNC Machining Services>CNC Milling Services

Home>CNC Machining Services>CNC Turning Services

Home>CNC Machining Services>Rapid Prototyping Services

Home>CNC Machining Services>Injection Molding Services

KYLT CNC Precision Machined Parts:

Home>Precision CNC Machined Parts

Home>Precision CNC Machined Parts>CNC Precise Turned Parts

Home>Precision CNC Machined Parts>CNC Precise Milled Parts

Home>Precision CNC Machined Parts>Aluminum Machining

Home>Precision CNC Machined Parts>Magnesium Machining

Home>Precision CNC Machined Parts>Copper & Brass Machining

Home>Precision CNC Machined Parts>Steel Machining

Home>Precision CNC Machined Parts>Stainless Steel Machining

Home>Precision CNC Machined Parts>Plastic Machining

More information about Machining Technology: