PLC 2000T High Speed High Pressure Aluminum, Copper/brass, Magnesium, Zinc(zamak)Metal Alloy Horizontal Cold Chamber Die Casting Machine

What is PLC 2000T High Pressure Die Casting Machine used for?

-PLC 2000T high pressure die casting machine normally used to cast large aluminum alloy parts which dosage of per inject can be reach (Alu.) 25.3/29.4/33.7/38.4/43.3KG.

-PLC 2000T high pressure die casting machine suitable for produce: Aluminum, Copper/brass, Magnesium, Zinc(Zamak) alloy parts of Automotive, motorcycle, filter, power tool, pneumatic tool, Electric power fittings , Door Closer, lamps and lanterns, explosion-proof products, pneumatic components, motor, diesel engine, gas oil machine, water pump, water heating equipments, desk & chair foots and arms, telecommunication,weapen etc military industrial and domestic lines.

PLC 2000T High Pressure Die Casting Machine Features:

1. Electrical System: adopts Mistsubishi, Omron or Schneider PLC control unit; casting parameters be adjusted from touch screen easily, which guarantee our 2000t high pressure horizontal cold chamber die casting working with stable, fast, safe and operation more reliable and precision.

2. Pressure & Speed Control: 2000T horizontal cold chamber die casting machine adopt Rexroth or Yuken proportional pressure valves and proportional direction valves, which have the functions of multi-stage pressure / speed control and mould clamping protect in low pressure.

3. Mould Platens: adopt High-quality nodular cast iron for mould platens which analysed and calibrated by finite-element method (FEM). All mould platens have features: reasonable pressure distribution, small deformation, high precison mould clamping. Whole 2000T die casting machine mould platens also showed: high rigidity, good abrasive resistance.

4. Hydraulic Oil Pump: imported famous brand duplex vane pump with high-performance and low-noice be used in 2000T PLC horizontal high pressure die casting machine.

5. Injection System: adopt independent accumulators, quick-injection and pressurize use newly developted rapid response throttle valves which increased the acceleration performance of quick-injection greatly, shorten the switching time of high-speed and pressurize. It is the symbol of advantageous injection performance of modern high quality PLC 2000T Horizontal High Pressure Aluminum, Copper/brass, Magnesium, Zinc(zamak) Metal Alloy Cold Chamber Die Casting Machine.

6. Lubrication System: adopt self-check joints, any blocks in oil passages can be respond fastly and easily. Underpressure protection system avoid the toggle parts of PLC 2000T die casting machine damagned from oil starvation, extend the die casting machine using time.

7. Precison Die Casting Machine Parts: all parts of 2000T die casting machine use CNC machining to guarantee precision.

8. Cold Assembly Processes: axle sleeves of 2000T PLC die casting machine adopts cooling assembly method to avoid parts deformation in assembling which keep the whole precision of high pressure die casting machine.

9. Tie bars: High strength alloy steel tie bars, surface with hard chromium plating to insure the die casting machine mould platens moving more stable, tie bars more wearable.

Top 10 Reasons to get PLC 2000T High Pressure Horizontal Cold Chamber Die Casting Machine:

--PLC 2000T DIE CASTING MACHINE JUST USE FAMOUS BRANDS SPARE PARTS.

1.Operation Panel language: English, Chinese (or as per client's demand)

2.PLC control: Mistsubishi, Omron,Schneider famous brand PLC can be chosen

3.Screen: TouchWin etc

4.Hydraulic pump: HYTEK etc

5.Valves: Rexroth, Yuken,HYTEK etc

6.Cooler: Longteng etc

7.Lubricate system: Liubian etc

8.Contactor: Schneider etc

9.Sealing system: Fischer etc

10.Hydraulic hose: AEROQUIP etc

(If needed, We should list all famous brand elements as per clien's requirements in contract. )

Detail Parameters for 2000T PLC Aluminum,Copper/brass,Magnesium,Zinc(zamak) Metal cold chamber die casting machine:

|

TYPE

|

2000T PLC

|

Aluminum, Copper/brass, Magnesium, Zinc(Zamak), Lead(Pb.) Metal High Pressure Cold Chamber Die Casting Machine with high pressure and speed

|

|

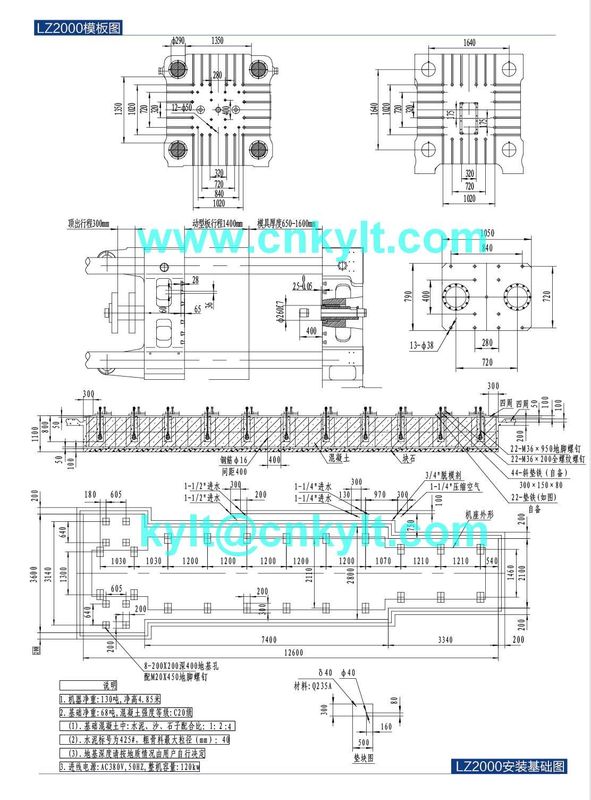

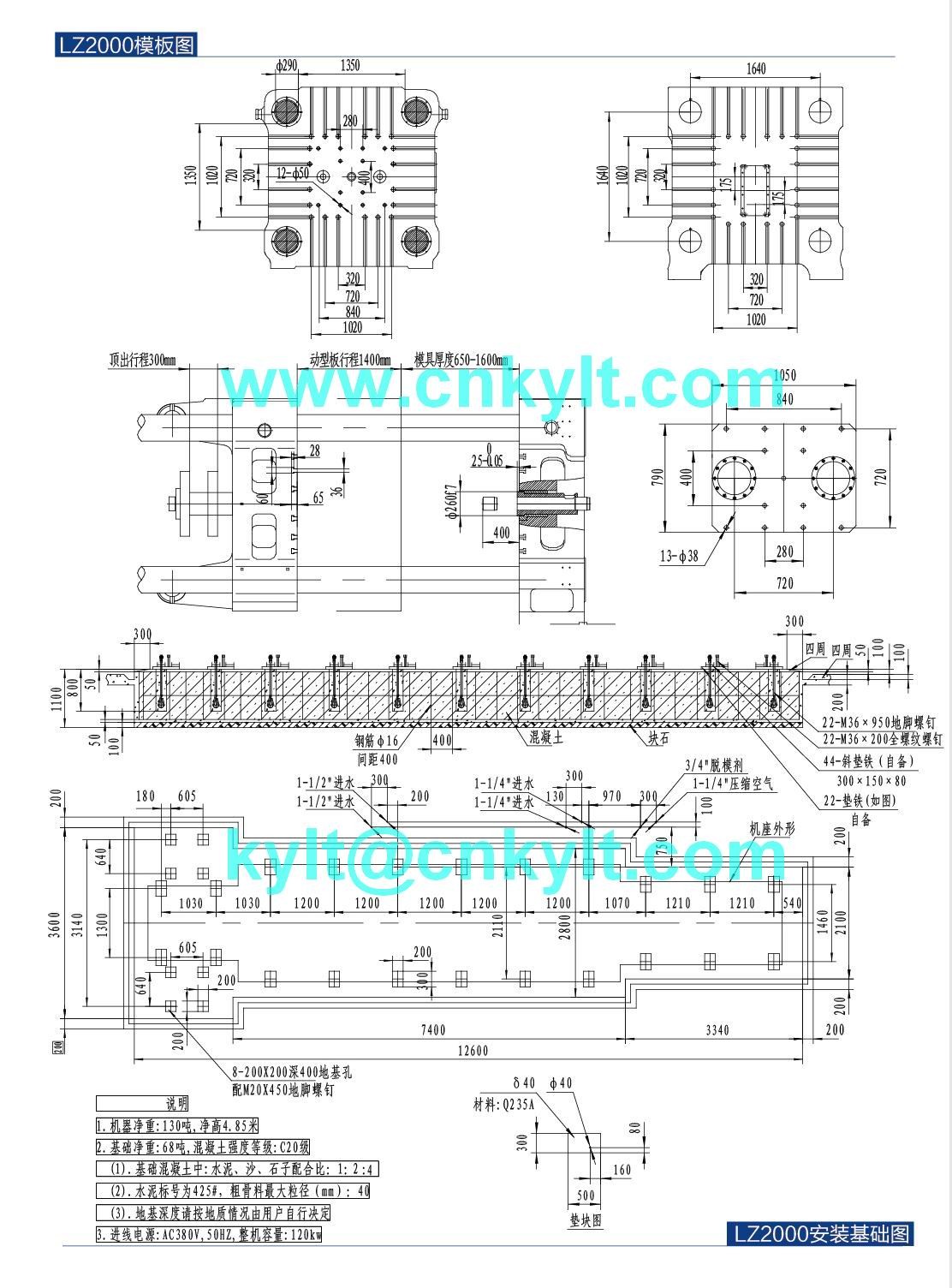

Die locking force

|

20000KN

|

Inner space between tie bars (H*V)

|

1350*1350MM

|

Bars dia.

|

290MM

|

|

Die thickness

(Min-Max.)

|

650-1600MM

|

Die stroke

|

1400MM

|

Ejection stroke

|

300MM

|

|

Ejection force

|

650KN

|

Injection force

(with intensification)

|

1500KN

|

Inject stroke

|

1020MM

|

|

Shot sleeve dia.

|

130/140/150/160/170MM

|

Dosage of fluid metal per inject (Alu.)

|

25.3/29.4/33.7/38.4/43.3KG

|

Casting pressure

(with intensification)

|

113/97/85/75/66MPa

|

|

Projection area of casting

|

1770/2062/2353/2667/3030CM2

|

Max casting area

|

5000CM2

|

Injection position

|

0,-175,-350MM

|

|

Over height of flange

|

25-0.05MM

|

Dia. of shot sleeve flange

|

260MM

|

Plunger penetration

|

400MM

|

|

Dry cycle

|

25S

|

Working pressure of pipes

|

14MPa

|

Motor power

|

55*2KW

|

|

Oil tank capacity

|

3000L

|

Machine weight

|

130000KG

|

Machine dimensions

(L*W*H)

|

13*3.8*4.8M

|

Die(mould) Platens / Die Fitting Diagram / Mounting Base Drawing of 2000T PLC Aluminum, Copper/brass, Magnesium, Zinc(zamak) Metal cold chamber die casting machine:

High Speed High Pressure PLC Aluminum, Copper/brass, Magnesium, Zinc(zamak), Lead(Pb.) Metal Alloy Horizontal Cold Chamber Die Casting Machine Tonnage list:

150T, 160T, 180T, 220T, 280T, 300T, 350T, 400T, 550T, 700T, 850T, 1100T, 1300T, 1600T, 2000T

Other names of cold chamber die casting machine:

aluminum zinc zamak alloy pressure die casting machine, aluminum zinc zamak pressure injection machine, magnesium alloy die casting machine, copper brass pressure die casting machine

2000T High Speed High Pressure PLC Aluminum, Copper/brass, Magnesium, Zinc(zamak), Lead(Pb.) Metal Alloy Horizontal Cold Chamber Die Casting Machine Price, Pls. contact as follows:

Contact Stone

Email: stonechenpeng@aliyun.com ; kylt@cnkylt.com

Skype: stone.chenpeng

Mob: 0086-15195010186

Msn: stonechenpeng@hotmail.com