12T Small Horizontal Hot Chamber Die Casting Machine has improved on the basis of other similar type machines. We adopts worldwide famous brands of electrical appliance and hydraulic component, high reliability, high efficiency of production, high automation. The zinc alloy, lead alloy and tin alloy which is manufactured by the machine has the good surface quality, and can be polishing, electrofacing, and spray lacquer. And it is widely used in manufacturing toy, lockset, fishing gear, hardware decorating parts, electrical and electronic casting, automobile part, watchcase, clothing metal accessory and so on.

12T Small Horizontal Hot Chamber Die Casting Machine Features:

-

Control panel with easy operation and safe locking protection design.

-

Reliable and durable automatic sprayer assures fast and stable production.

3. The improved melting furnace adopts advanced design and material, more energy saving and durable.

4. Mold closing/opening adopts electronic fix detecting system, and its precision is higher.

5. The alarm information can be found conveniently and timely.

6. Injection operation, opening and locking mould design etc. can be set on the screen rapidly and accurately.

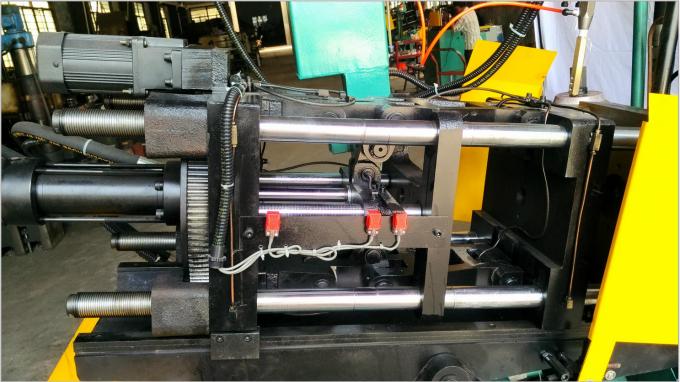

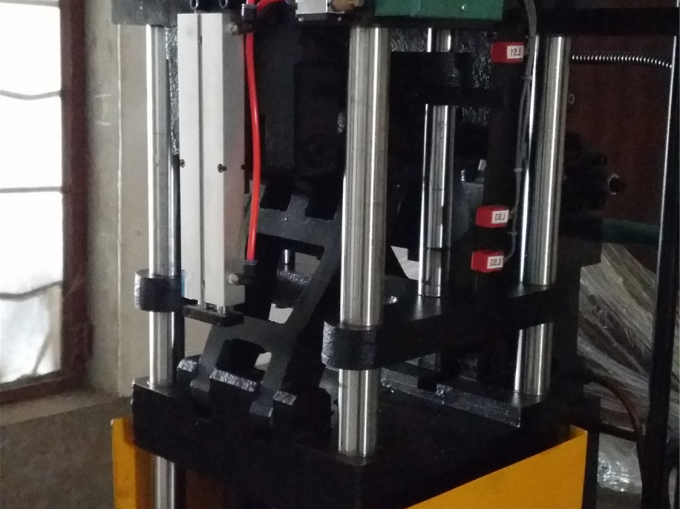

7. High-strength steel alloy tie bar with chromium plated for high wear resistance and long service life.

8. Thickened platen was made of excellent ductile cast iron with high rigidity, even stress and little distortion, which ensures the stability of die casting machine.

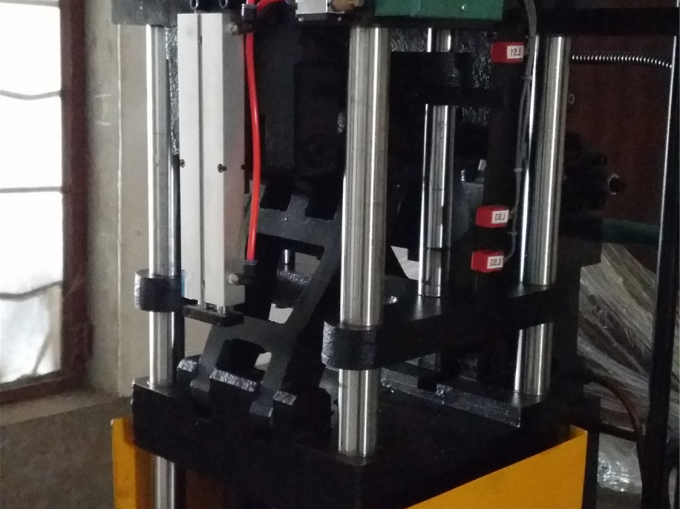

9. Diagonal five point toggle was made of ductile cast iron with high rigidity, high durability, and more stable mold opening and closing.

10.The heat treated parts of the injection system are made of high-quality hot processed steel.

12T Small Horizontal Hot Chamber Die Casting Machine Specifications and Parameters:

|

ITEMS & TYPE

|

Parameters |

| 12T |

| Locking Force |

120Kn |

| Tie Bars Inner Space |

190×220mm |

|

Moving Platen

Stroke

|

120mm |

| Profiling Thickness |

110 – 190mm |

| Injection Pressure |

14Kn |

| Injection Stroke |

55mm |

|

Dosage of Fluid

Metal Per Shot

|

Zn:100g |

| Crucible Effective Capacity |

Zn.70Kg |

| Motor Power |

4Kw |

| Accumulator Capacity |

6.3L |

| Working Pressure |

6.2Mpa |

|

Electric Heating

Tube Power

|

6.9Kw |

| Heater Power |

1Kw |

| Oil Tank Capacity |

170L |

| Machine Weight |

~ 1100Kg |

| Machine Size |

220×80×180cm |

| Vane Pump |

28L/min |

Usage of small hot chamber die casting machine:

Small Hot chamber die casting machine widely used for low melting point alloys. Zinc/zamak die casting parts, lead alloy die casting parts, tin alloy die casting parts etc.

Mostly the machine always be used to produce zinc alloy die casting parts, the machine also named: zinc die casting machine, zinc injection machine.

Compare with cold chamber die casting machine, this machine is small. Its key function is injection work, so it also called: small die casting machine, small zinc injection machine, small high pressure inject machine.

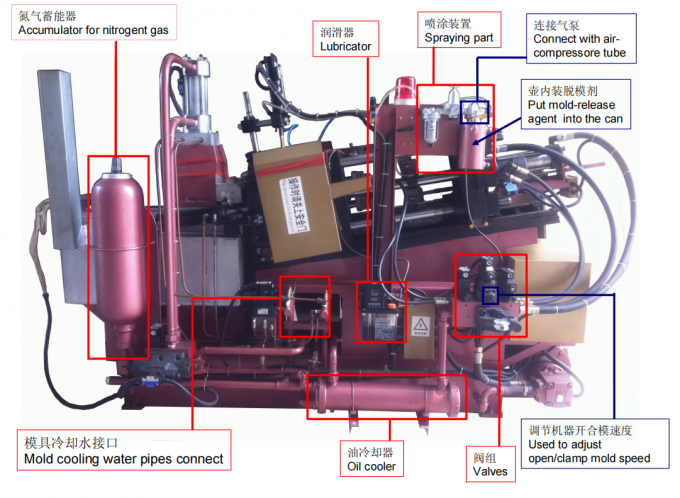

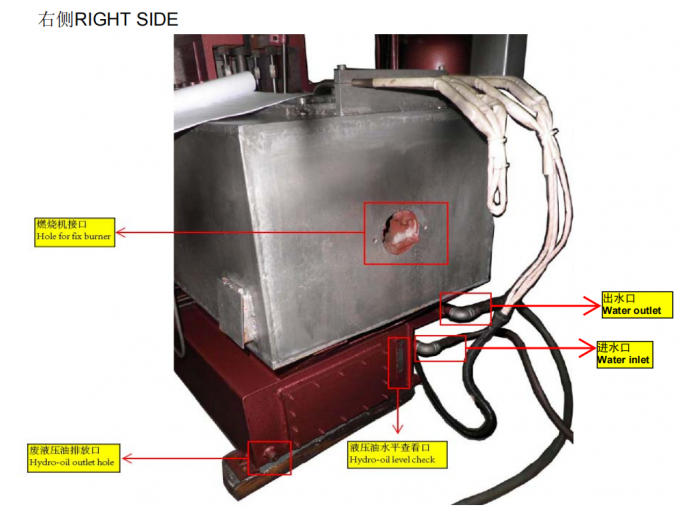

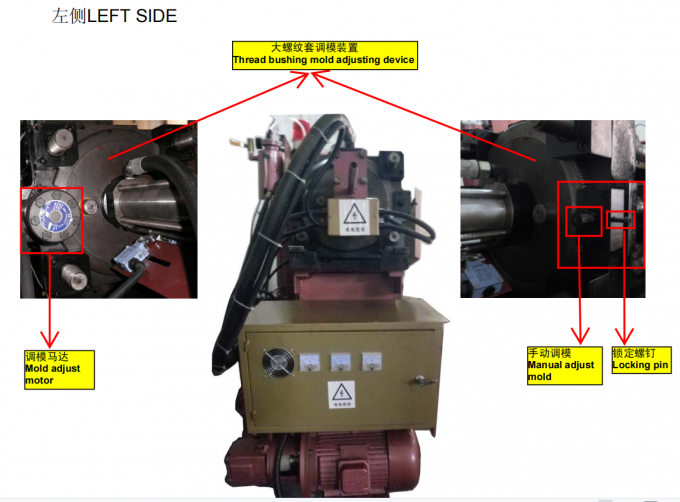

Small hot chamber horizontal die casting machine details structures:

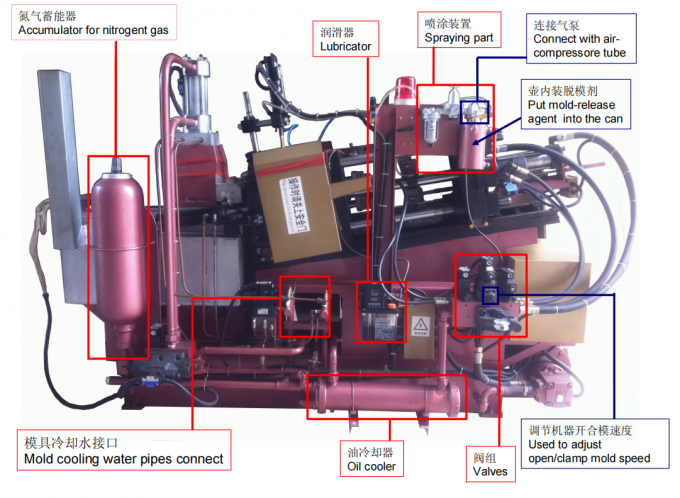

Small hot chamber machine contains a melting furnace pot, machine body & base, clamping mold mechanism, accumulator, hydraulic system etc. Now, we will show you the small hot chamber horizontal die casting machine details structures:

1. Front structure of hot chamber machine:

2. Back side of hot chamber pressure die cast machine:

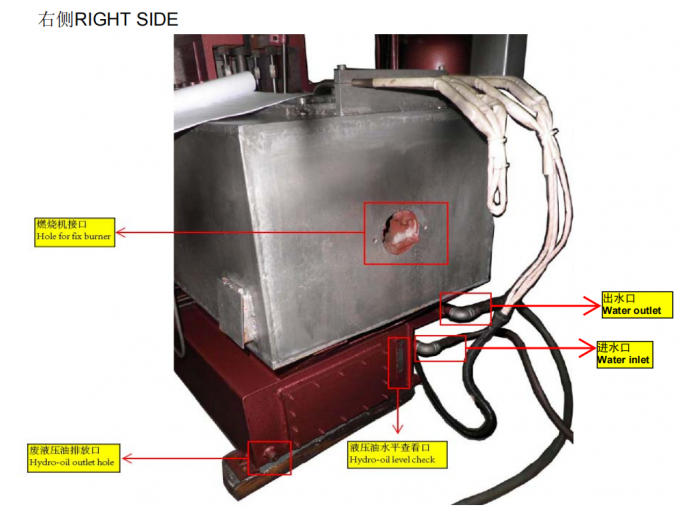

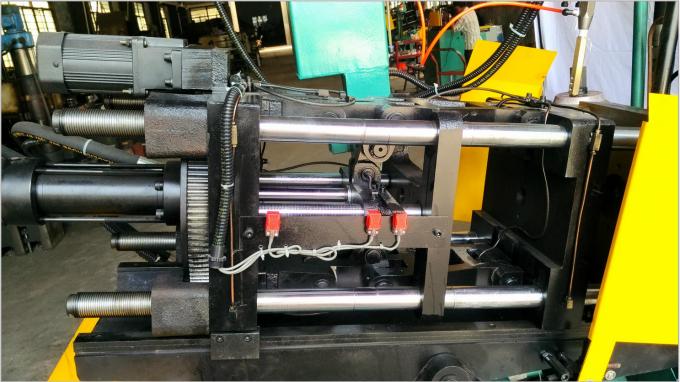

3. Horizontal hot chamber die casting machine right side structure:

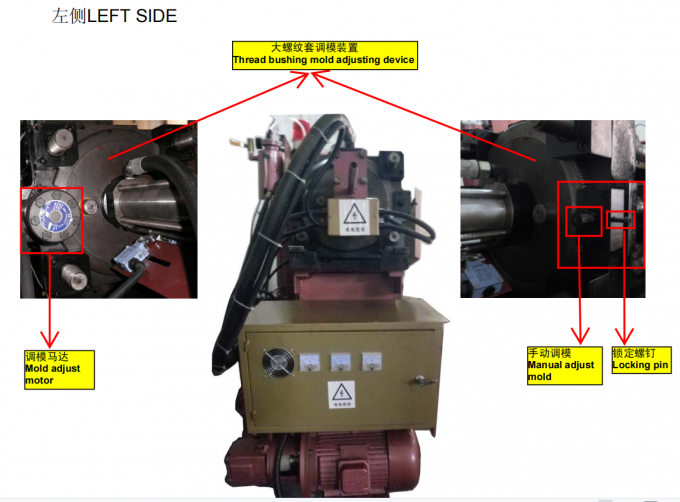

4. Hot chamber pressure injection machine left side structure:

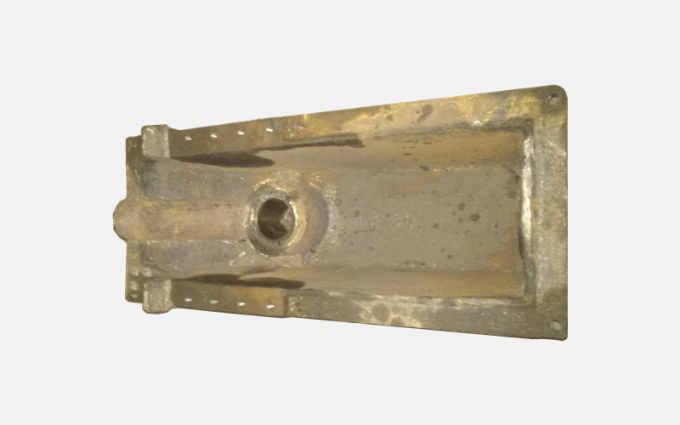

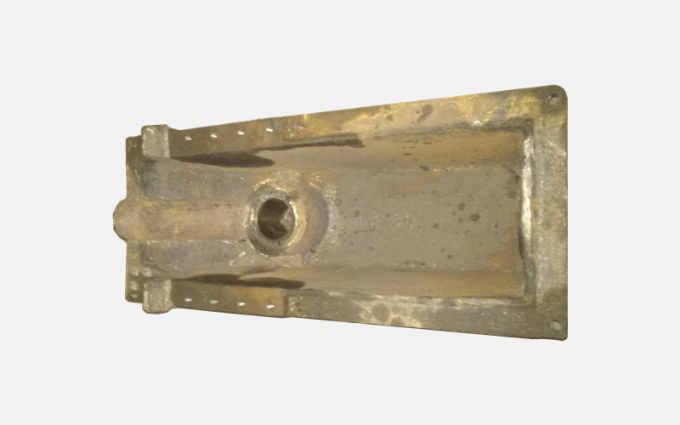

The advantages of HD special melting pot goose-neck structure:

Special designed goose neck structure with pot, which keep alloy melting leverl same with injection nozzle. That reduce the air sapce of gooseneck to mold cavity. Finished die casting parts inside air holes are reduced sharply.

-

Pot material made from special stainless iron.

-

Molten metal alloy flow into hot chamber directly.

-

Gooseneck structure be cast together with pot.

-

Gooseneck structure connect with nozzle, which has a designed angle to keep molten metal level same with nozzle hole. That avoid many air be push into mold cavities.

Machine base is a hydraulic tank. It bears the furnace and machine body. Die casting machine body key structure is the clamping mechanism. The contains guide ways, mold platens, mold adjusting system etc.

Die casting machine pressure from the hydraulic station. Accumulator used to balance the machine pressure.

What is the hot chamber die casting working process?

1.Melting Furnace Pot

Electric heating tubes heat metal alloy to molten state. (If first time use the melting pot, no alloy cover the electric heating tubes, we need pour molten alloy to the pot or use burner to melt metal blocks in pot firstly. When metal alloy covers the heating tubes, machine electric heating method can be used. )

2. Hot Chamber Injection Process

1st. Die casting die is clamped and the injection plunger rises, opening the hot chamber hole, allowing molten metal flow into the chamber cylinder.

2nd.The plunger seals the hot chamber hole, pushing the molten alloy through the gooseneck and nozzle into the mold cavities where it is held under pressure until metal alloy solidifies.

3rd.After the metal has solidified in the cavity, the plunger is withdrawn.

4th. Die casting machine movable platen move back and mold opens. Die casting parts be eject out from movable die half by ejector pins.

5th.Lubricating and cooling mold cavity. Die casting mold temperature is about 150℃.

6th.Mold closes and to start the next injection cycle.

More about hot chamber die cast process please view video:

1. Full auto horizontal die casting machine video https://youtu.be/k2nq4q4CYao

2. 12T vertical die casting machine video https://youtu.be/6yC_AQaJMTU

3. 20T vertical die casting machine fishing bait making https://youtu.be/SliYJiJdz5I

4. 20T zinc end wire casting machine L-type machine https://youtu.be/0bVZTJE6zT4

5. 20T vertical wire zinc end die casting machine (wires position locking mechanism-wire retainer)

https://youtu.be/56BcfLUQAOw

About the cold chamber die casting process please view video:

1. Manual cold chamber die casting machine video:

https://www.youtube.com/shorts/npYbgva3NK8

2. Auto cold chamber die casting machine video:

https://www.youtube.com/watch?v=LCafa6yLESc

About small 12T horizontal die casting machine price, or die casting mould, please feel free to email us: cnkylt@aliyun.com We will choose suitable machine types, suggestions of mould design, provide free die casting samples.

Related Casting Machinery:

Die Casting Machine

· Battery Spine Die Casting Machine

· Cold Chamber Die Casting Machine

· Hot Chamber Die Casting Machine

· Vertical Die Casting Machine

· PDC casting machine

Material

· Aluminum Die Casting Machine

· Magnesium Die Casting Machine

· Copper Die Casting Machine

· Zinc Die Casting Machine

· Lead Die Casting Machine

Application

· Auto Parts Die Casting Machines

· Kitchen &Household Parts Die Casting Machines

· Lamps Light Parts Die Casting Machines

· Electric Vehicle Spare Parts Die Casting Machines

· Hardware, Jewelry, Clothing Accessories Die Casting Machines

· Tel-Communication Equipment Parts Die Casting Machines

· Garden Machinery & Electric Tools Parts Die Casting Machines

· Lead Acid Battery Terminal Bushing, Battery Positive Spine Grid Die Casting Machines

· Fishing Sinker Die Casting Machines

· Others