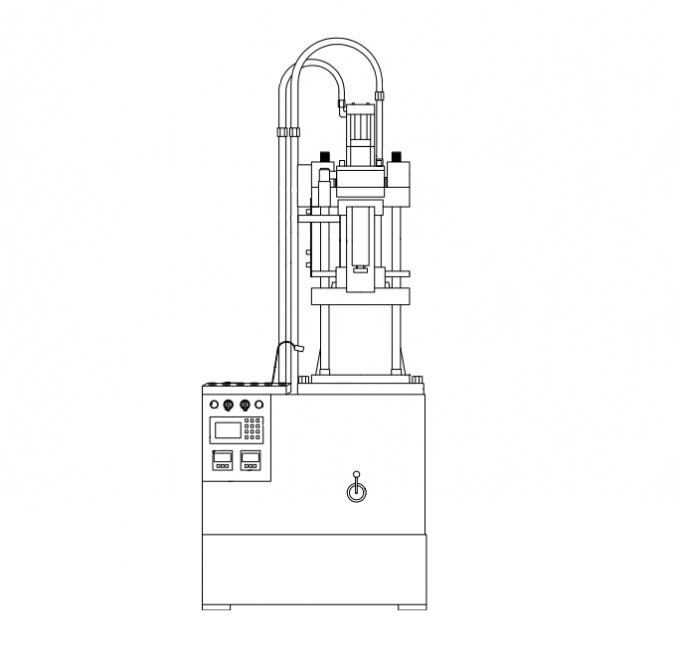

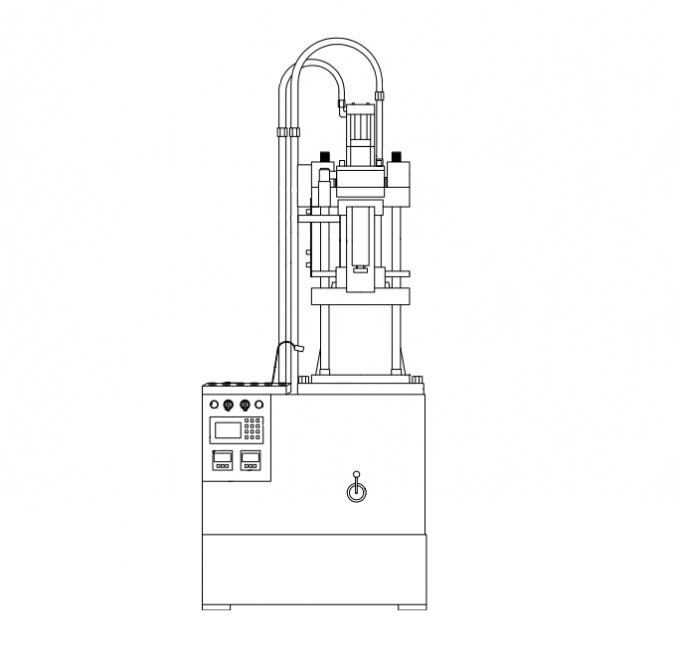

Vertical die casting machine used cast Zn( Zinc/Zamak), Pb(Lead), Sn(Tin) alloy parts. As the vertical design, easy for opeator to set insert part. Such as: brake wire/cable, fishing sinker (Luya), bolt terminal of lead acid battery, battery terminal clamp connector pile head etc. More information, please email: cnkylt@aliyun.com

Hot Chamber Vertical die casting machines types: 12T, 20T, 30T. They are can be used cast Zinc/Zamak Alloy, Lead Alloy die casting parts, and those parts have inserts must be cast together with Zinc or Lead alloy.

Vertical die casting machines structure consists of machine body, mold clamping mechanism, injection system, cooling system, melting furance, electric system etc.

Cast machine adopts hydraulic drive, electric operation, and has manual and automatic operation. Melting furance is heated by electrical heated tube, so its operation is easy, and it has big adjustment range and wide application scope. The brand of hydraulic valve, time relay, general relay, AC contactor, microswitch of this machine is domestic and oversea famous, so it is running stable and performing excellence. It runs efficiently after adjustment. This machine is suitable for zinc alloy, lead alloy and tin alloy casting of hardware, electrical appliance, tool industry etc.

What are the vertical hot chamber die casting machines used for?

Vertical hot chamber die casting machine normally used to produce zinc or lead alloy parts with have insert parts which must be cast together. Such as brake wires of car and bike, fishing sinker, lead metal fishing lure, lead Luya bait, lead acid battery terminal with bolt etc.

Brake wire/cable making

To cast zinc terminal with wirerope. The manufacturing process need: die casting machine, die casting die, wireropes. Operator manual set wireropes on mold cavities. Normally 12T machine one time set 6 wireropes, 20T can set 8 wireropes.

The machine can be used to cast bike wire cable, motorcycle brake wire, car brake cable or wirerope with zinc end terminal.

Video for brake wire zinc end die casting machine test:

https://www.youtube.com/watch?v=cBZXtBaEbAk

Lead alloy metal fishing sinker, lead metal fishing lure, lead Luya bait making

As ring, hook and other metal piece need be cast together with lead alloy to produce fishing parts. Vertical lead alloy injection machines are used, with the horizontal operating platform, worker can set metal insert to mold cavties easily and conveniently. The manufacturing of small lead (Pb.) alloy fishing parts use 12T vertical type, for big Luya bait need use 20T vertical type.

Video for vertical die casting machine fishing bait making

https://youtu.be/SliYJiJdz5I

Lead acid battery terminal with bolt, copper nut manufacturing

Vertical die casting machine can set bolts, nut, copper insert in mold cavites easily. In lead acid battery terminal making process, those metal insert parts can be set in good positions.

Vertical hot chamber die casting machine specification:

12T high pressure vertical hot chamber die casting machine parameters:

| Name |

Parameters |

Name |

Parameters |

|

| Locking Force |

120Kn |

Motor Power |

3.75Kw |

|

| Tie Bars Inner Space |

190×220mm |

Accumulator Capacity |

6.3L |

|

| Moving Platen Stroke |

100mm |

Working Pressure |

8Mpa |

|

| Profiling Thickness |

110 – 190mm |

Electric Heating Tube Power |

7.5Kw |

|

| Injection Pressure |

14Kn |

Heater Power |

1Kw |

|

| Injection Stroke |

55mm |

Oil Tank Capacity |

120L |

|

| Dosage of Fluid Metal per shot(Zn) |

130g |

Machine Weight |

About 1000Kg |

|

| Crucible Effective Capacity(Zn) |

70Kg |

Machine Size |

120×90×210cm |

|

| Oil Pump |

28L/min |

20T high pressure vertical hot chamber die casting machine parameters:

| Name |

Parameters |

Name |

Parameters |

|

| Locking Force |

200Kn |

Motor Power |

3.75Kw |

|

| Tie Bars Inner Space |

235×245mm |

Accumulator Capacity |

16L |

|

| Moving Platen Stroke |

125mm |

Working Pressure |

7.0Mpa |

|

| Profiling Thickness |

110 – 190mm |

Electric Heating Tube Power |

7.5Kw |

|

| Injection Pressure |

20Kn |

Heater Power |

1Kw |

|

| Injection Stroke |

72mm |

Oil Tank Capacity |

170L |

|

| Dosage of Fluid Metal pershot(Zn/Pb) |

Zn:220kg

Pb:500g

|

Machine Weight |

About 1450Kg |

|

| Crucible Effective Capacity(Zn/Pb) |

Zn:110kg

Pb:130-150Kg

|

Machine Size |

200×90×240cm |

|

| Oil Pump |

28L/min |

30T pressure vertical hot chamber metal alloy injection machine parameters:

| Name |

Parameters |

Name |

Parameters |

| Locking Force |

300KN |

Motor Power |

5.5KW |

| Tie Bars Inner Space |

345×295mm |

Accumulator Capacity |

16L |

| Moving Clamping Plate |

125mm |

Vane Pump Working Pressure |

7.0Mpa |

| Profiling Thickness |

110 – 190mm |

Electric Heating Tube Power |

9.5KW |

| Injection Pressure |

30KN |

Heater Hand Power |

1KW |

| Injection Stroke |

120mm |

Oil Tank Capacity |

170L |

| Dosage of Fluid Metal Per shot Pb) |

1000g |

Machine Weight |

~2500Kg |

| Crucible Effective Capacity(Pb) |

300Kg |

Machine Dimensions |

170×90×250cm*2Parts |

| Vane Pump |

30L/min |

|

|

Vertical die casting machine types:

There are 3types vertical die casting machines to meet customers' demand: L type, T type, S type.

1. L type vertical die casting machine

This vertical machine melting furance pot is at right angle with clamping mechanism and control panel. The whole machine structure view like letter "L". That is the reason we call it as L type machine.

Vertical L type machine is standard structure. We have two kinds tonnages: 12T, 20T.

2. T type high pressure hot chamber vertical die casting machine

Vertical T type hot chamber die casting machine developed on the standard horizontal hot chamber die casting machine. T type machine body and melting furance are same the with horizontal machine. Machine clamping mechanism is at right angle with machine body. The whole machine structure like inverted letter "T", that is the reason we call this machine is T type.

Our 200kn T type vertical hot chamber die casting machine is speical ordered by a world famous brake wire manufacturer. They need auto robots in front and back side of the machine. T type machine has more space to set wire cutting robot in machine front. Back side has enough space to set pick-up and stamping robots. Metal alloy be melted in the machine right side furance by electric tubes. Nozzle injects molten alloy from bottom of fixed mold platen to mold cavities at right angle.

Video for zinc end wire casting machine L-type machine

https://youtu.be/0bVZTJE6zT4

Video for vertical wire zinc end die casting machine S-type (wires position locking mechanism-wire retainer)

https://youtu.be/56BcfLUQAOw

3. S type vertical pressure hot chamber inject die casting machine

300kn (30T) vertical die casting machine is separeted two parts. One part is melting furance and clamping machanism. Another part is electric control system, accumulator, hydraulic station etc.

Vertical die casting machine maintenance schedule:

| No. |

Check position |

Check item |

Check standard |

| 1 |

die-casting machine |

machine environment |

the machine is clean, and also clean the around of the machine |

| 2 |

security system |

security door |

no loose, run stably and reliably |

| air cylinder of security door |

air cylinder no leakage, piston rod no drags, and signal recption is good |

| 3 |

lubricantion system |

oil level of lubrication oil tank |

between the top and bottom limitation |

| lubrication effect |

add machine oil at every lubrication position, and without oil leakage |

| 4 |

hydraulic system |

total pressure |

work pressure is good, pressure shake doesn't influence normal work, oil pump without noise |

| oil level of hydraulic oil tank |

overwhelm oil gauge entirely |

| hydraulic oil temperature |

between 55℃- -10℃ |

| oil valve, oil pipe |

surface is clean, no loose, and no leakage |

| hydro-cylinder, piston rod |

oil tank is no leakage, piston rod is no drags, and good connection |

| 5 |

gas pressure system |

pressure gage of atomized lubricator |

5-6Bar setting requires 5-6Bar |

| ramming material air cylinder |

air cylinder is no leakage, piston rod is no drags |

| the gas of ramming material air cylinder |

no moisture |

| pressure gage of atomized lubricator |

oil quantity keep between top and bottom limitation |

| 6 |

mechanical system |

tie bar ( draglink) |

surface is clean, no drags, and no injury |

| template |

no injury, surface is clean |

| cross guide rod |

surface is clean, no abrasion and drags |

| anti-loose |

mode locking piston rod and cross hold-down nut is no loose, and steel pin set screw clamp spring is no loose |

| 7 |

electric system |

indicator light |

indicator light of power, lubrication, running is on when working |

| operation panel |

button is good and fixed solidly |

| wire |

be tied solidly and no damage |

| emergency stop switch |

can cut off the motor power when press it |

| stroke switch |

function of on-off is good, no greasy dirt, screw is no loose, pulley is no abrasion, probe is no breakage and no displacement |

| proximity switch |

surface is clean, no loose and no displacement |

| 8 |

hot work temperature |

smelter temperature |

adjust the temperature to 350℃ when start, and keep for 20mins, then adjust to working temperature |

| nozzle head |

lift the machine frame, and check if the nozzle head is leaking |

| 9 |

cooling system |

cooling pipeline |

no water seepage |

| |

|

|

|

|

| |

periodic table of maintenance |

| serial no. |

maintenance position |

maintenance content |

maintenance standard |

maintenance period |

| 1 |

lubricantion system |

strainer, oil tank |

wash by diesel |

2 months/time |

| lubrication pipeline, lubrication parts |

lubrication pipeline is unimpeded, change damaged parts |

1 week/time |

| add engine oil into oil nozzle |

add engine oil |

1 day/time |

| 2 |

hydraulic system |

hydraulic oil |

sampling check |

half year/time |

| hydraulic oil |

change 1/3 hydraulic oil |

1 year/time |

| nitrogen pressure |

no leaking |

1 week/time |

| oil cylinder sealing element |

no oil leaking, no burn-in, and change the parts of burn-in (suggest to check and change before summer) |

1 year/time |

| strainer, oil tank |

wash by diesel oil and check if there is damage |

half year/time |

| oil pump |

oil can come out normally, no abnormal noise |

1 year/time |

| piston rod, piston head, cylinder bush, oil valve |

no galling, abrasion and fragmentation |

1 year/time |

| 3 |

mechanical system |

screw |

fastening |

3 months/time |

| crank |

steel bush, steel pin and crank is no abrasion (steel bush and steel pin should be changed every year) |

1 year/time |

| pulley wheel |

no scratch and displacement |

half month/time |

| mold adjustment device |

no abrasion and work normally |

half month/time |

| template copper bush |

no abrasion |

1 year/time |

| cross guide rod, copper bush |

no abrasion and galling |

1 year/time |

| parallelism of template |

|

half year/time |

| coaxiality, verticality |

|

1 year/time |

| security door |

can rotate and move easily |

half month/time |

| steel band |

no abrasion and galling |

half year/time |

| 4 |

electric system |

stroke switch |

change |

1 year/time |

| wire terminal |

check and fasten all the wire terminals |

3 months/time |

| electrical appliance box |

keep clean and no dust, no bare wire |

3 months/time |

| contactor, relay contact |

no scorch and oxidation |

3 months/time |

| relay, time relay |

change |

1 year/time |

| proximity switch |

fasten screw and clean the dust |

2 months/time |

| motor |

no shake and abnormal noise |

1 year/time |

| operation panel |

check all the buttons if there is loose or damage |

2 months/time |

| 5 |

hot work system |

thermocouple |

surface is no corrosion, if the temperature probe is good |

half month/time |

| |

molten cup pressing plate |

check if it is loose |

3 days/time |

| 6 |

cooling system |

pipeline |

if it is leaking |

1 month/time |

| |

cooler |

if it is blocking |

half year/time |

Vertical die casting machine free spare parts list: