What is Die Casting Machine - Die Casting Machine Types, Die-casting mould & Die casting parts

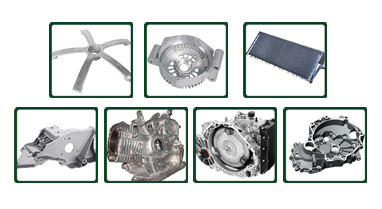

Die casting process, by injecting molten metal under pressure into die casting dies or molds. Die casting mould consists two halves: fixed die half, movable die half. Metal shapes are formed by mold cavity. When mold open, we can obtain the cast metal parts.

The machine which used to finish the die casting process is named Die casting machine. It has two mechanism: Cold chamber & Hot Chamber.

Here, we will introduce the equipment for this process, what is die casting machine, die casting machine types, their mechanism & features, how to choose suitable die casting machine.

What is Die Casting Machine?

Hot Chamber Die Casting Machine

Hot chamber die casting machine is mainly used for producing ZAMAK/Zinc alloy die casting parts, the low melting point metal such as Tin & Lead/PB alloy are allowed also. (Normally we use ZAMAK3, ZAMAK 5)

Hot chamber machine injection mechanism is immersed in melting pot. The melting furnace pot attached with die casting machine by gooseneck. The injection cylinder plunger push molten metal alloy through goose-neck structure to machine mould cavities. When mold open, we can got the finished die casting parts. One hot chamber die casting process is finished.

ZAMAK Alloy types (Zinc alloy types):

ZAMAK is a family of alloys with varying compositions. The most common types of ZAMAK alloys are:

-

ZAMAK 3: This alloy has a composition of approximately 4% aluminum, 1% copper and the balance zinc. It is the most widely used ZAMAK alloy due to its excellent castability and dimensional stability.

-

ZAMAK 5: This alloy has a composition of approximately 4% aluminum, 1% copper, and 3% magnesium. It has higher strength and hardness than ZAMAK 3 but is less ductile.

-

ZAMAK 2: This alloy has a composition of approximately 3% aluminum, 3% copper, and the balance zinc. It has good mechanical properties and is commonly used in applications where high impact resistance is required.

-

ZAMAK 7: This alloy has a composition of approximately 0.005% magnesium, 0.03% copper, 0.001% iron, 0.002% lead, 0.001% cadmium, and the balance zinc. It has good castability and is often used in decorative applications due to its ability to produce fine detail.

-

ZAMAK 8: This alloy has a composition of approximately 8% aluminum, 3.5% copper, and the balance zinc. It has excellent casting characteristics and is often used in applications where high strength is required.

Note that these compositions may vary slightly depending on the manufacturer, but they generally fall within the ranges specified above.

Hot Chamber Die Casting Machine Types:

1. Horizontal Hot Chamber Die Casting Machine:

This type is full automatically, used to produce: clothes accessories, zipper puller and slider, jewelry, electric parts, lead acid battery PB parts etc. 20T tonnage machine suitable used to produce Zamak/Zinc alloy clothes accessories, zipper puller and slider, jewelry. 20T-30T tonnage machine suitable used to produce PB alloy parts.

2. Vertical Hot Chamber Die casting Machine:

This type is semi-auto, used to produce casting parts with insert. It is convenient to set insert parts in mould cavities. Use to produce Fishing sinker, Luya Bait, Fishing Bait, brake wire zinc end etc.

Advantages of hot chamber die casting machine

– High productivity

– Complex part structure allowed

– Long die casting mold life

– Precision tolerance

Cold Chamber Die Casting Machine

Cold Chamber Die Casting Machine suitable for Aluminum alloy, Zinc/ZAMAK alloy, Magnesium alloy, Copper alloy and Lead alloy casting. All those metal alloys be cast with high pressure. Molten metal be forced into mold cavities through cold chamber by plunger. A cold chamber die casting unit, molten metal from a separate melting furnace is ladled into the cold chamber sleeve after the mold is closed. That is the key feature of cold chamber die casting.

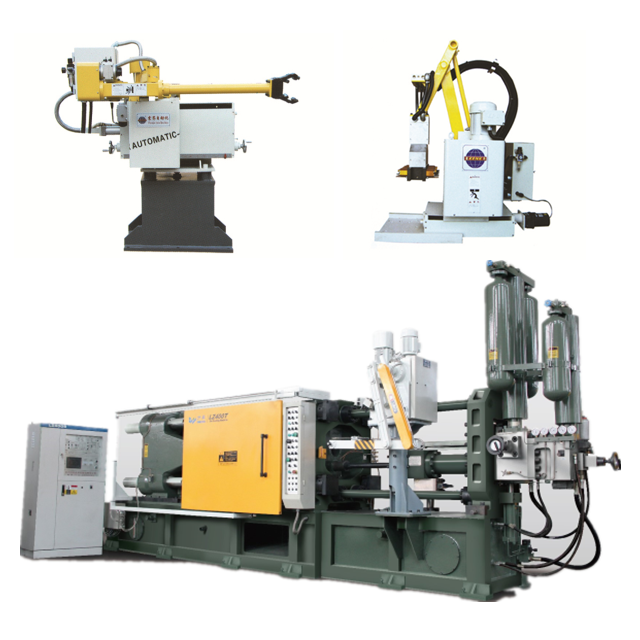

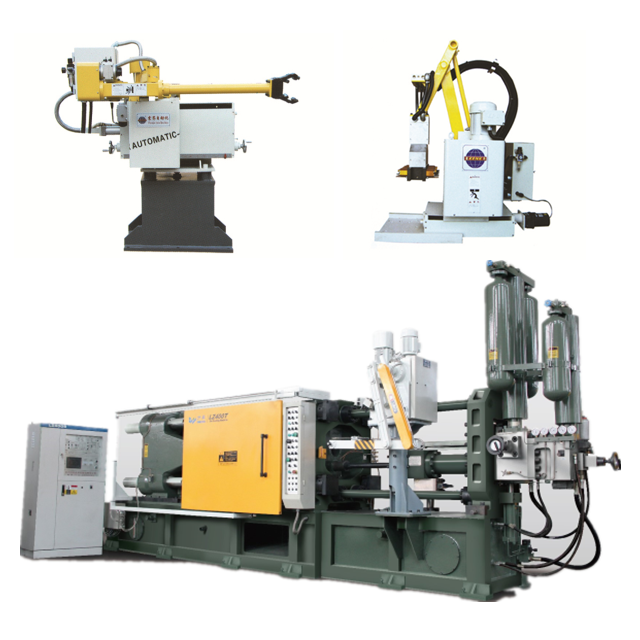

Cold Chamber Die Casting Machine unit main consist two sections: horizontal cold chamber die-casting machine, aluminum melting furnace. With a die casting mould, the manual aluminum die casting process is established.

Cold Chamber Die Casting Machine working methods:

There are two methods: Manual, Automatic

-

Manual die casting work process: die casting opeartor pour molten aluminum alloy from furance to cold chamber, then casting machine inject metal to die tool to get the die casting parts.

Video of manual die casting method: https://youtu.be/p4yfwbCPTgU

2. Full automatic die casting work process:

Die casting machine PLC control the whole process. Automatic ladler pour molten aluminum metal alloy from melting pot to die casting machine cold chamber. Then, be inject to mold cavities to got die-cast parts. Auto extractor pick-up casting part from die tool, put them on conveyor. The auto sprayer cooling and lubricating the mold cavity. And, to start then next die casting process.

Full automatic aluminum cold chamber die casting unit working process video: https://youtu.be/npYbgva3NK8

Advantages of cold chamber die casting machine

– High melting point alloys allowed

– Easy to assemble

– Large parts can be produced

How to choose suitable die casting machine?

Which die casting machine should be choosed? That depends on the usage and metals. The aluminum/copper/magnesium die casting parts must use cold chamber die casting machine, the separate furnace can melt high melting point alloys. If your products is Zinc/Zamak, tin and lead material, you should choose a hot chamber die casting machine, because they are low melting point alloy, machine pot can melt them directly. The high temperature used in casting aluminum and copper alloys will shorten the life of hot chamber machines. On the contrary, cold chamber casting machines are more suited to casting high melting-point metals like aluminum or alloys with a high aluminum content.

Die casting machines application:

-

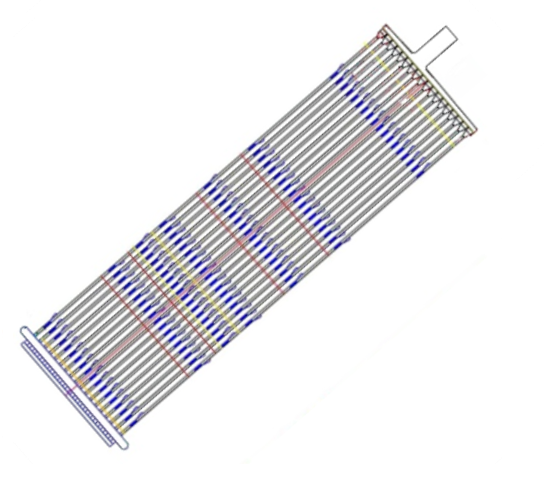

220-300T cold chamber die casting machine for iron sole plate making

-

550T cold chamber die casting machine to make Baking tray, Casserole, Saute Pan, Milk Pan, Fry Pan, Grill Pan, Wok, Pan Cake, Multi-Use Pan, Hamburger Maker etc.

-

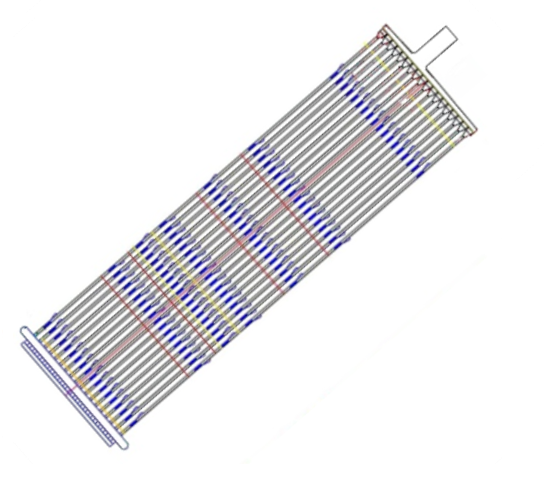

Lead acid battery positive spine making

-

Brake wire cast with zinc/zamak terminal

-

Lead fishing sinker/Luya making

More information about Die Casting Machines Service & Price, Please email us: cnkylt@aliyun.com

Related Casting Machinery:

Die Casting Machine

· Battery Spine Die Casting Machine

· Cold Chamber Die Casting Machine

· Hot Chamber Die Casting Machine

· Vertical Die Casting Machine

· PDC casting machine

Material

· Aluminum Die Casting Machine

· Magnesium Die Casting Machine

· Copper Die Casting Machine

· Zinc Die Casting Machine

· Lead Die Casting Machine

Application

· Auto Parts Die Casting Machines

· Kitchen &Household Parts Die Casting Machines

· Lamps Light Parts Die Casting Machines

· Electric Vehicle Spare Parts Die Casting Machines

· Hardware, Jewelry, Clothing Accessories Die Casting Machines

· Tel-Communication Equipment Parts Die Casting Machines

· Garden Machinery & Electric Tools Parts Die Casting Machines

· Lead Acid Battery Terminal Bushing, Battery Positive Spine Grid Die Casting Machines

· Fishing Sinker Die Casting Machines

· Others